In an era where efficiency and precision are paramount, the integration of technology into operational processes has become essential. The rise of Remote Monitoring Pumps exemplifies this trend, offering organizations a transformative approach to manage resources and optimize performance. According to Dr. Emily Chen, a leading expert in automated water systems, “Remote Monitoring Pumps are revolutionizing the way we manage fluid systems by providing real-time data and predictive analytics that enhance decision-making.”

This powerful tool not only ensures timely interventions but also boosts operational efficiency by minimizing downtime and reducing maintenance costs. The ability to monitor various parameters—such as flow rates, pressure levels, and potential malfunctions—remotely empowers organizations to maintain a continuous flow of operations while minimizing manual oversight.

Moreover, as environmental concerns grow, the adaptability of Remote Monitoring Pumps makes them a vital component for sustainability efforts. By maximizing performance and resource management, these smart pumping solutions not only cater to the operational needs but also align with the global commitment to energy efficiency and reduced operational footprints. As we explore the top benefits of these systems, it becomes clear that embracing Remote Monitoring Pumps is not just an option, but a necessity for modern operational excellence.

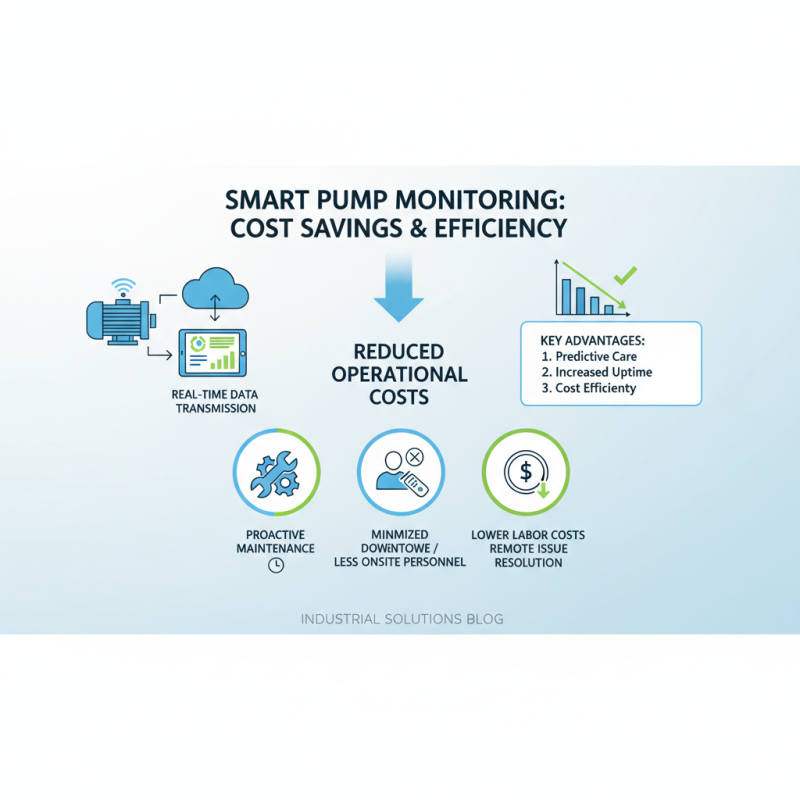

Remote monitoring pumps offer significant advantages in reducing operational costs for businesses across various industries. By utilizing real-time data transmission, these pumps enable organizations to monitor their systems remotely, leading to proactive maintenance and minimized downtime. This capability reduces the need for onsite personnel and lowers labor costs, as technicians can address issues from a distance instead of traveling to multiple locations to conduct inspections.

Moreover, remote monitoring pumps enhance energy efficiency, which is another critical factor in controlling operational expenses. By providing constant feedback on performance metrics, these systems allow for adjustments in real time, helping to optimize energy usage. As a result, companies can achieve substantial savings on their utility bills while also extending the lifespan of their equipment through timely interventions and maintenance scheduling. Overall, the integration of remote monitoring technology not only streamlines operations but also significantly cuts costs, making it an invaluable asset for resource-conscious organizations.

Remote monitoring pumps are becoming a game-changer in various industries, particularly in sectors where resource efficiency is paramount. These advanced systems utilize IoT technology to provide real-time data analytics, enabling operators to optimize resource usage effectively. According to a recent industry report by MarketsandMarkets, the global remote monitoring market is projected to reach USD 40 billion by 2026, reflecting a compound annual growth rate (CAGR) of 28% from 2021. This substantial growth underscores the increasing adoption of technologies that enhance operational efficiency.

One of the notable benefits of remote monitoring pumps is their ability to minimize downtime through predictive maintenance. By constantly tracking performance metrics and alerting operators to potential issues before they escalate, these systems help organizations save on both time and costs associated with emergency repairs. A report by McKinsey indicates that predictive maintenance can reduce machine downtime by 20-50%, thereby increasing overall productivity.

Tips: To maximize the efficiency of remote monitoring pumps, ensure that your system is equipped with strong cybersecurity measures to protect sensitive data. Additionally, regularly train staff on interpreting the data collected to foster a proactive maintenance culture. Incorporating these practices will not only enhance your operations but also extend the lifespan of your equipment significantly, leading to even greater resource efficiency.

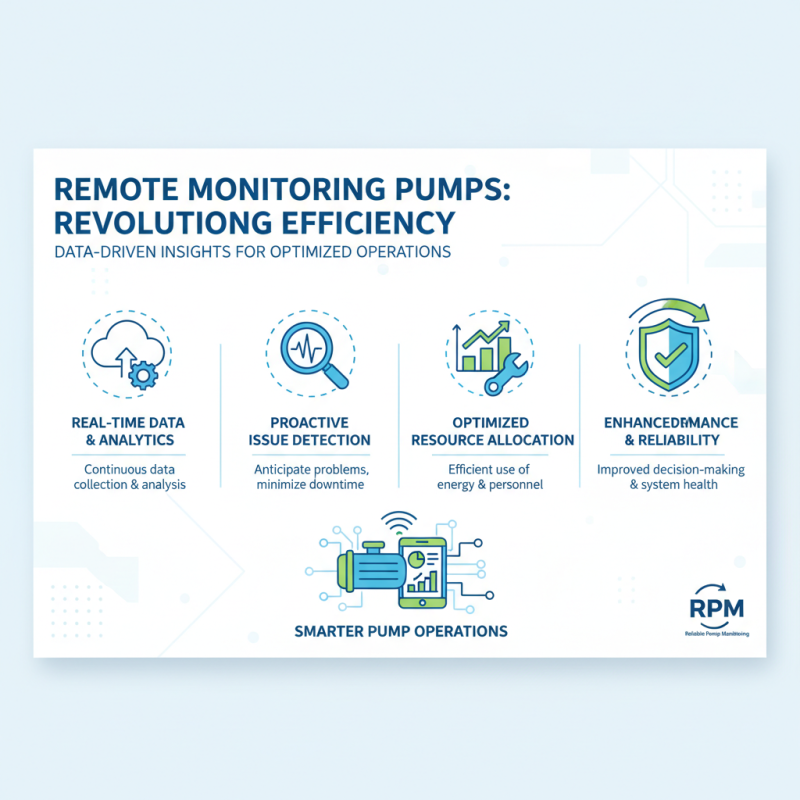

Remote monitoring pumps are revolutionizing operational efficiencies by integrating advanced analytics into their systems. The use of data-driven insights enables organizations to gain a comprehensive understanding of their pump operations, leading to improved decision-making and enhanced performance. By continually collecting and analyzing real-time data, businesses can identify patterns, track performance metrics, and anticipate potential issues before they escalate. This proactive approach not only minimizes downtime but also optimizes resource allocation and energy consumption.

Analytics play a crucial role in remote monitoring systems, transforming raw data into actionable intelligence. Through analytical tools, operators can visualize trends and make sense of complex data sets, allowing them to implement targeted strategies that enhance system reliability. For instance, predictive analytics can forecast maintenance needs, reducing the risk of unexpected failures and increasing the lifespan of equipment. Furthermore, these insights can help in evaluating the effectiveness of different operational strategies, leading to continuous improvement in processes. Ultimately, the integration of analytics in remote monitoring systems fosters a more responsive and adaptable operational environment.

Remote monitoring pump technology is revolutionizing the industrial landscape by enhancing safety standards in operations. According to a recent report by the International Society for Automation, the implementation of remote monitoring systems has led to a 30% reduction in workplace accidents related to pump malfunctions. These systems not only allow for real-time monitoring but also enable predictive maintenance, significantly minimizing risks associated with equipment failures.

Tips for improving safety with remote monitoring include regularly updating software to ensure optimal performance and security. Consistent training for personnel on how to interpret data from these systems can further enhance situational awareness, leading to quicker response times during anomalies. By harnessing the power of data analytics, organizations can anticipate issues before they escalate, creating a safer work environment.

Moreover, integrating mobile access to monitoring systems empowers operators to stay informed even when away from the site. Reports indicate that facilities utilizing mobile remote monitoring experience a 20% increase in incident response efficiency. This ensures that safety protocols can be upheld even in the most dynamic environments, reinforcing the commitment to a safe and efficient operation.

Real-time monitoring solutions have transformed the operational landscape for industries reliant on remote monitoring pumps. By providing continuous feedback on performance metrics, these systems enable operators to detect anomalies early, thus preventing unexpected failures that can lead to costly downtime. The integration of advanced sensors and communication technologies allows for the monitoring of key metrics such as pressure, flow rate, and temperature from anywhere, ensuring that the equipment is functioning optimally.

Furthermore, the ability to analyze real-time data empowers organizations to make informed decisions quickly. When issues arise, remote monitoring systems offer alerts and diagnostics, allowing technicians to address the problem before it escalates. This proactive approach not only enhances the reliability of operations but also maximizes the uptime of the equipment. By minimizing interruptions and ensuring consistent performance, businesses can improve their overall productivity and operational efficiency. Implementing such solutions means that companies can focus on their core activities rather than being continuously reactive to equipment failures.

This chart illustrates the key benefits of using remote monitoring pumps in terms of increasing uptime and reliability through real-time monitoring solutions. The measurements indicate improvements in operational efficiency, maintenance reduction, and overall reliability.