When it comes to selecting a Vortex Pump, understanding your needs is crucial. The market offers a variety of options tailored for different applications. Each product has unique features and specifications, which can be overwhelming.

Choosing the best Vortex Pump requires careful analysis. Various factors come into play, such as flow rate and energy efficiency. Some users may find it tough to navigate through the choices. Clarity and purpose are essential in this selection process.

This guide aims to simplify your decision. We will explore the top Vortex Pumps available in 2026. Get ready to discover which models might suit your specific needs. Let’s dive into the details and find the perfect match for your applications.

Vortex pumps are specialized devices designed to handle fluid movement effectively. They operate using a unique mechanism that creates a vortex motion within the pump casing. This motion is essential for drawing in and expelling the liquid. The process happens quickly, making them efficient for various applications.

These pumps are particularly useful in situations with high solids content. For instance, in wastewater treatment, they can manage thick slurries without clogging. Their design minimizes contact between the fluid and moving parts. This aspect reduces wear and tear, enhancing the pump's lifespan. However, one must consider the limitations of vortex pumps. They may struggle with very high-viscosity fluids and might not be as effective in low-flow conditions.

When selecting a vortex pump, think about your specific needs. The right choice depends on factors like flow rate and the types of materials being pumped. Some users report slight inefficiencies in certain scenarios, which requires careful thought. Continuous monitoring of performance might be your best option. Adjustments may be necessary as operational conditions change.

| Pump Model | Flow Rate (GPM) | Maximum Head (ft) | Power (HP) | Applications |

|---|---|---|---|---|

| Model A | 150 | 40 | 3 | Industrial, Agriculture |

| Model B | 200 | 50 | 5 | Wastewater, Irrigation |

| Model C | 175 | 45 | 4 | Mining, Construction |

| Model D | 250 | 60 | 6 | Pumping Sludge, Heavy Liquids |

When selecting a vortex pump, focus on a few key features that can determine overall performance. Flow rate is crucial. This metric indicates how much fluid can be moved over time. Most industrial applications require specific flow rates, often ranging from 50 to 500 gallons per minute. Ensure the pump you choose meets your requirements.

Consider the pump's material as well. Corrosion resistance is vital for longevity, especially in harsh environments. For example, pumps made from stainless steel or polycarbonate often outperform standard materials. A recent industry report noted that 75% of pump failures were linked to material degradation. This statistic emphasizes careful material choice.

Lastly, inspect the pump's efficiency rating. An efficient vortex pump can save on energy costs significantly over its lifespan. According to data from the Pump Systems Matter Initiative, optimizing pump efficiency can lower energy expenses by up to 30%. This not only benefits the environment but also the bottom line. Reflecting on these factors can lead to smarter purchasing decisions.

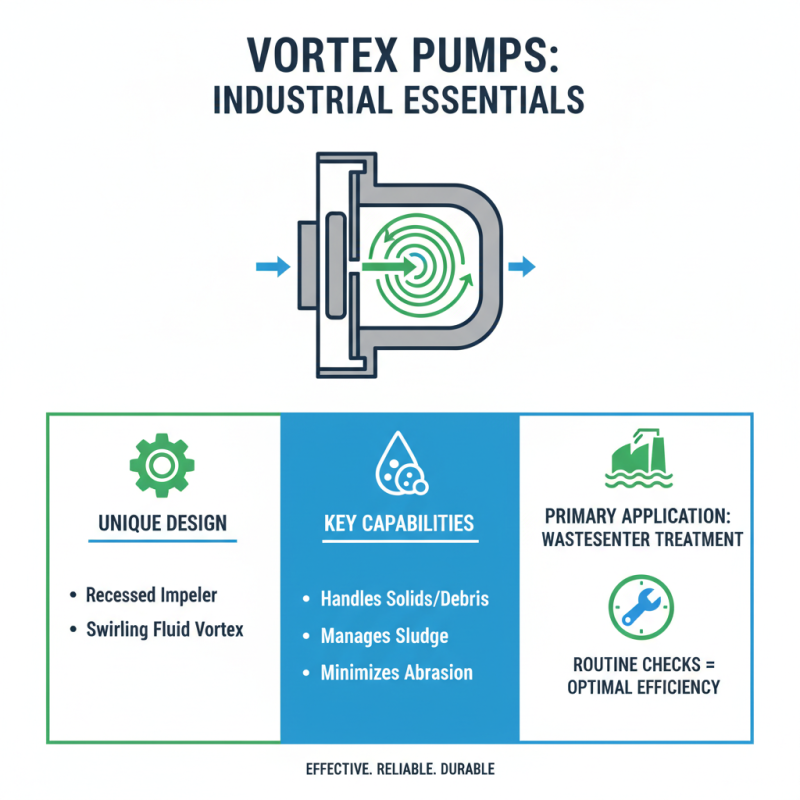

Vortex pumps are essential in various industries due to their unique design and capabilities. They effectively handle fluids with solid particles, making them suitable for wastewater treatment. In this field, these pumps can manage debris and sludge, ensuring a smooth operation. Their ability to handle abrasive materials minimizes wear, yet they still require routine checks to maintain efficiency.

In mining and construction, vortex pumps shine when dealing with slurry and sediment. Their performance is reliable, but challenges can arise when particles are too large. In such cases, a thoughtful evaluation of the application is necessary. These pumps also find applications in chemical industries, where the movement of viscous fluids is common. It’s important to assess how the pump materials interact with the chemicals, as improper choices can lead to failures.

Despite their strengths, vortex pumps aren't foolproof. Users must regularly monitor their conditions. Clogs might occur, especially if maintenance is neglected. Operators should always be prepared for unexpected interruptions. Understanding the specific needs of each application is crucial for optimizing pump performance.

When considering the best vortex pumps in 2026, it's crucial to compare leading models. Vortex pumps are widely used in various applications, from wastewater treatment to industrial manufacturing. According to a 2023 market analysis, the global vortex pump market is projected to grow at a CAGR of 6.2% over the next five years. Understanding the features of different models can be overwhelming.

New vortex pump designs focus on efficiency and durability. Many models now incorporate energy-efficient motors, which can reduce operational costs significantly. Reports indicate that pumps with high-quality impellers can increase reliability and extend service life. However, not all manufacturers provide detailed performance data, which can leave users uncertain when making a choice.

Maintenance plays a crucial role in the performance of vortex pumps. Regular checks can prevent breakdowns and ensure optimal operation. Interestingly, many operators neglect routine maintenance, leading to reduced efficiency. Figures suggest that around 30% of vortex pump failures result from inadequate upkeep. It's essential to thoroughly evaluate maintenance requirements before settling on a model.

Vortex pumps are essential in various applications. Regular maintenance is key to keeping them running smoothly. Here are some effective maintenance tips to enhance their performance.

Firstly, check the impeller regularly for wear or damage. Impeller issues can lead to decreased efficiency. Clean components often to prevent debris accumulation. This buildup can disrupt flow and cause cavitation. Examine seals and gaskets for any signs of deterioration. Small leaks can develop into bigger problems.

Additionally, monitor the pump's operating conditions. Ensure it runs within the recommended pressure and temperature ranges. Overheating can damage internal parts. Consider regularly reviewing the operating manual for specific guidelines. This helps in understanding its unique needs and identifying potential issues early on. Neglecting these maintenance tasks may lead to costly repairs down the line.