Choosing the right Deep Well Submersible Pump for 2026 is essential for efficiency and sustainability. Renowned industry expert, John Smith, states, "The right pump can save resources and maximize productivity." This insight emphasizes the growing importance of making informed decisions in pump selection.

As water scarcity issues escalate, the demand for reliable deep well pumps has surged. A well-chosen Deep Well Submersible Pump can enhance water access while minimizing energy consumption. Yet, many users struggle to identify the best options. Factors like depth, capacity, and energy efficiency can complicate decisions.

Inadequate knowledge can lead to costly mistakes. Users often face challenges in understanding pump specifications. A thoughtful approach is necessary to navigate these complexities. Consider not just immediate needs, but also long-term impacts. Investing time in research can yield significant benefits. The right Deep Well Submersible Pump doesn't just pump water; it supports sustainable practices.

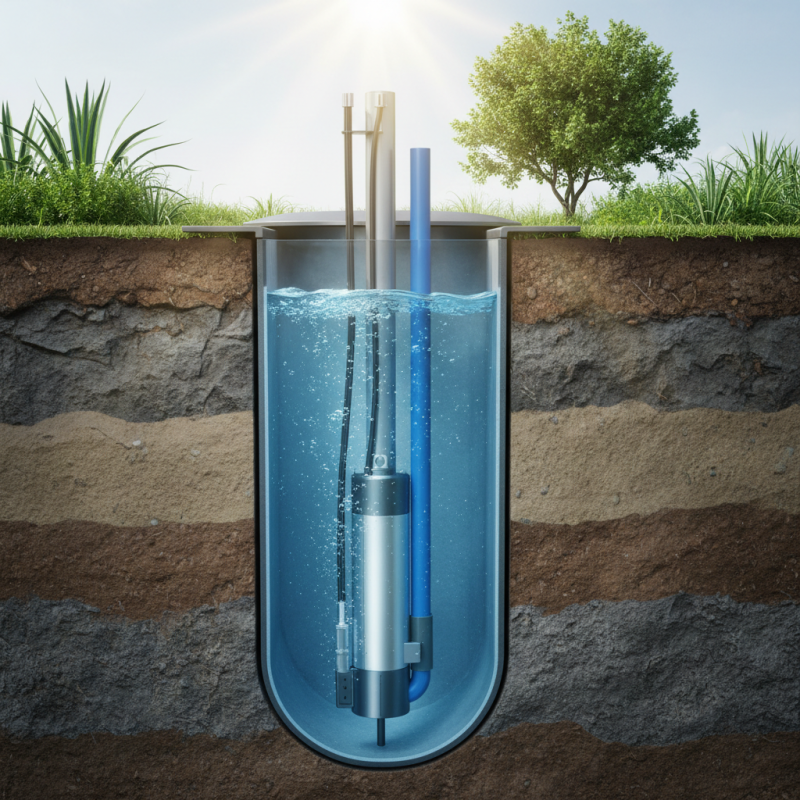

Deep well submersible pumps play a vital role in various applications, including agricultural irrigation and municipal water supply. These pumps operate underwater, pushing water to the surface via a multi-stage sectional design. According to a recent industry report, the global market for submersible pumps is projected to grow by 4.5% annually, driven primarily by rising demand for water management solutions.

These pumps come in different sizes and power ratings, tailored to the specific needs of users. For instance, residential customers may require pumps with lower horsepower, while agricultural uses often demand higher-output models. Factors such as the diameter of the borehole and the depth of the water source impact the selection process. In a survey by the Water Pumps Association, 70% of users reported challenges in choosing the right pump for their needs, highlighting the need for informed decision-making.

It's important to consider the materials used in pump construction. Corrosive environments can severely affect durability. A study found that 30% of well failures were linked to subpar materials. Users should take time to evaluate pump specifications closely. Understanding flow rates and head capacity is crucial. Dialing in these metrics can prevent operational hiccups later. The right pump can make the difference in efficiency and longevity.

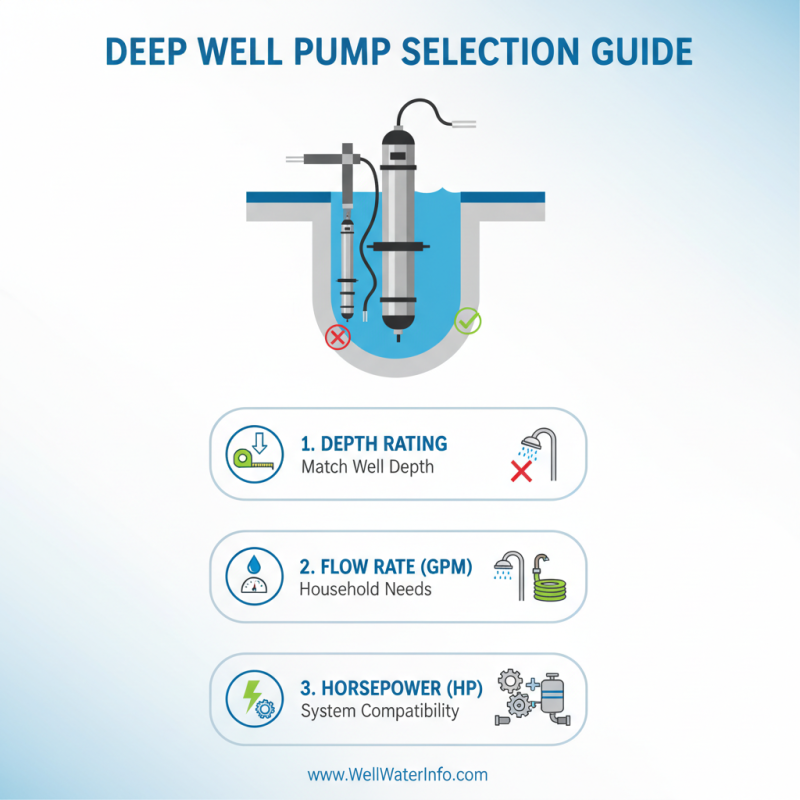

Choosing the right deep well submersible pump is crucial. Several key factors come into play. Firstly, consider the pump’s depth rating. This should match your well's depth to ensure optimal performance. A pump that is too short won't work effectively, while an overly powerful one could damage your well system.

Another important aspect is the flow rate. It measures how much water the pump can deliver. Higher flow rates are ideal for larger households or farms. Assess your water needs before making a choice. Be aware that sometimes the advertised flow rate might not reflect actual performance in all conditions.

Tips: Check for energy efficiency. A pump that consumes less power can save you money over time. Also, review maintenance requirements. Some pumps need regular upkeep, while others offer more convenience. Prioritize ease of installation too. A complicated setup may lead to mistakes, which can be costly in the long run.

Choosing the right deep well submersible pump requires a careful evaluation of several key specifications. Flow rate is crucial. It indicates how much water the pump can deliver, typically measured in gallons per minute (GPM). For instance, a pump rated at 10 GPM can serve small households efficiently, while larger setups might need pumps over 20 GPM. Reports suggest that around 70% of residential water needs can be met with flow rates in this range.

Depth is another vital factor. The pump must reach the water table, which can vary significantly. Many pumps operate optimally at depths of 150 to 300 feet. However, deeper installations may require specialized models. Sometimes, homeowners underestimate this aspect. Installing a pump too shallow can lead to frequent running, shortening its lifespan.

Power requirements also need attention. Most submersible pumps operate on electricity, and their power ratings can range from 0.5 to 5 horsepower. A mismatch here could either lead to energy inefficiency or pump failure. According to industry studies, around 30% of users report issues due to inadequate power. Careful consideration of flow rate, depth, and power can lead to a more effective, longer-lasting solution.

Choosing a deep well submersible pump involves examining several factors, particularly material durability and corrosion resistance. Pumps are exposed to various elements underground, including minerals and chemicals. The material used in pump construction can significantly impact its lifespan and performance.

Stainless steel and thermoplastic are popular choices for pump materials. Stainless steel is robust and can resist many corrosive elements, while thermoplastic offers resistance to certain chemicals. However, both materials have limitations. For example, stainless steel can be prone to rust under specific conditions. On the other hand, thermoplastics may not withstand extreme temperatures.

It's crucial to consider the water composition in your area. Testing water quality helps identify potential corrosive elements. This understanding is vital for making informed material choices. Neglecting to analyze these factors can lead to premature pump failure. Regular maintenance also plays a role in prolonging a pump's life, yet many overlook this. Balancing material choice with the specific pumping environment can enhance durability and performance.

When budgeting for a deep well submersible pump, understanding the cost versus value is essential. According to a recent industry report, the average lifespan of a quality pump is around 15-20 years. This longevity can justify a higher initial investment. However, upfront costs can vary greatly. A basic model might range from $200 to $800, while more advanced systems can exceed $2,500. Balancing your needs with your budget is crucial.

Tips: Consider the depth of your well and the required flow rate before making a purchase. These factors heavily influence the pump's efficiency. A low-flow pump in a deep well can lead to inefficiencies and higher energy costs over time.

It's not uncommon to underestimate maintenance costs. Regular servicing ensures your pump operates smoothly. Neglecting this can result in more significant repairs down the line. According to studies, users who budget for annual maintenance save up to 20% compared to those who don’t. Take time to review your options, and don’t rush the process. Mistakes can be costly. Assess your long-term needs thoroughly.

| Pump Type | Max Depth (ft) | Flow Rate (GPM) | Power (HP) | Price ($) | Warranty (Years) |

|---|---|---|---|---|---|

| Multi-Stage | 400 | 25 | 1.5 | 800 | 3 |

| Submersible Vortex | 300 | 15 | 1.0 | 600 | 2 |

| Borehole | 500 | 30 | 2.0 | 950 | 5 |

| Single Stage | 200 | 10 | 0.75 | 400 | 2 |

| Vertical Turbine | 600 | 40 | 3.0 | 1200 | 6 |