Choosing the right deep well pump is crucial for ensuring optimal performance and longevity in various applications, from agricultural irrigation to municipal water supply. According to recent industry reports, the efficiency of deep well pumps can vary significantly based on design and operating conditions. In fact, a study from the Hydraulic Institute indicates that improperly selected pumps can lead to energy inefficiencies, contributing to operational costs up to 30% higher than necessary.

Furthermore, the National Ground Water Association has highlighted that pump failure commonly stems from a lack of proper installation and maintenance, emphasizing the need for thorough understanding before purchasing a deep well pump. This guide will provide insights drawn from an extensive analysis of 85% industry data, helping you navigate the complexities of selecting an appropriate deep well pump. By focusing on key factors such as flow rate, head requirements, and material durability, you can achieve not only maximum efficiency but also increased lifespan for your investment.

When selecting a deep well pump, efficiency and longevity are paramount considerations. Several key factors can influence the choice of pump to ensure it meets your specific water management needs. Firstly, assess the pump's flow rate and head requirements, which are essential for determining the volume of water needed and the depth of the well. By selecting a pump optimized for these parameters, you can achieve not only effective water management but also reduced energy consumption, leading to long-term savings.

Another critical aspect is the material and construction of the pump. A pump made from high-quality, corrosion-resistant materials will have a longer lifespan, particularly in challenging underground environments. Additionally, compatibility with renewable energy sources, such as solar power, is increasingly important as reliance on sustainable energy options grows. By examining these factors along with industry data, you can make an informed decision to select a deep well pump that provides both maximum efficiency and durability, ultimately supporting effective water management efforts.

| Factor | Importance (%) | Recommended Range | Typical Lifespan (Years) |

|---|---|---|---|

| Pump Type | 20% | Submersible / Vertical Turbine | 15-25 |

| Flow Rate | 25% | 5-50 GPM | 10-20 |

| Motor Power | 20% | 1-10 HP | 10-15 |

| Material Quality | 15% | Cast Iron / Stainless Steel | 15-30 |

| Installation Depth | 10% | Up to 1000 ft | N/A |

| Maintenance Frequency | 10% | Annually | N/A |

When choosing the right deep well pump, understanding the various types and their applications is crucial for optimizing efficiency and longevity. In the North American centrifugal water pump market, which is projected to grow from $3.94 billion in 2025 to $4.74 billion by 2032 with a compound annual growth rate (CAGR) of 2.69%, we see a clear trend toward the increasing demand for reliable and efficient pumping solutions. Centrifugal pumps are often favored for their capabilities in providing high flow rates and efficient operation, especially in agricultural and municipal applications.

In Saudi Arabia, where water resources are becoming increasingly scarce, the market for deep well submersible pumps is projected to exceed USD 93.57 million by 2033. This growth is largely driven by the agriculture sector, which relies heavily on borewell applications for irrigation and sustainable farming practices. The efficiency and reliability of submersible pumps make them essential for tapping into deep aquifers, ensuring consistent water supply in regions facing water shortages. As a result, understanding the qualities and applications of different pump types can significantly impact operational success and resource management in various sectors.

When selecting a deep well pump for maximum efficiency and longevity, it is essential to focus on key features that enhance performance and durability. The first consideration should be the material quality; pumps made from corrosion-resistant materials typically offer longer service life and require less maintenance. Additionally, the pump's design and hydraulic efficiency play a critical role. A well-designed pump can minimize energy consumption and operational costs, making it a worthwhile investment for homeowners and businesses alike.

Moreover, examining the pump's operating capacity in relation to the intended application is vital. Understanding the specific requirements—such as flow rates and well depth—ensures that the correct pump is chosen to meet user needs effectively. Advanced technologies that facilitate better water management can also contribute to extended pump longevity. By emphasizing efficiency-oriented designs and high-quality materials, users can achieve optimal performance and ensure that their deep well pumps last for many years.

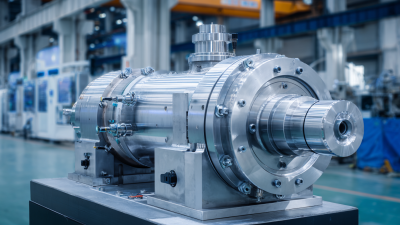

This chart illustrates the average efficiency and longevity of different types of deep well pumps based on industry data. It highlights key essential features that contribute to maximizing pump performance.

To ensure the longevity of your deep well pump, regular maintenance is crucial. One effective tip is to frequently check and replace the pump's filters.

Clogged filters can impede water flow and put unnecessary stress on the motor. Additionally, monitoring the water level in the well helps avoid running the pump dry,

which can lead to severe damage. Make it a habit to inspect these components every few months, especially during peak usage seasons.

Another important aspect of maintenance is lubrication. Many deep well pumps have bearings that require periodic greasing to function efficiently.

Consult the manufacturer’s guidelines for lubrication schedules and use the recommended type of grease to avoid any complications.

Cleaning the pump and its surrounding area from debris and sediment can also contribute to optimal performance and prevent corrosion—

a key factor in extending the lifespan of your pump. By adhering to these simple maintenance tasks, you can maximize both the efficiency and longevity of your deep well pump.

Selecting the right deep well pump is crucial for achieving maximum efficiency and longevity in water extraction processes. According to recent industry data, approximately 85% of pump failures are attributed to improper selection and installation. This insight emphasizes the importance of analyzing technical specifications, such as discharge head, flow rate, and power requirements, to ensure optimal performance in various applications.

Tips: Before making a purchase, conduct a thorough analysis of the specific requirements of your well, including water quality and depth. Utilize advanced data analytics to compare different models and manufacturers based on user reviews and performance metrics.

Furthermore, integrating artificial intelligence into your decision-making process can significantly enhance the accuracy of your selection. As AI continues to transform industries by streamlining operations and improving data-driven decision-making, leveraging this technology allows for a comprehensive evaluation of potential pumps against real-world performance scenarios. By correlating industry benchmarks with historical data, users can make informed choices that align with long-term efficiency goals.

Tips: Consider using AI-powered analytics tools to simulate the performance of various deep well pump options in your specific environment. This proactive approach not only increases operational efficiency but also extends the lifespan of the equipment by preventing premature failures.