When it comes to industrial pumping solutions, choosing the right equipment matters. Shield Pump stands out in this competitive market. These pumps are known for their reliability and robustness. Industries require machinery that performs under pressure. Shield Pump meets these demands effectively.

The design of the Shield Pump is tailored for efficiency. Its durability minimizes breakdowns and downtime. This means fewer disruptions in operations. Many companies have experienced increased productivity using these pumps. However, not all Shield Pumps are created equal. Some models may not suit every industrial need perfectly.

Investing in a Shield Pump is a decision that requires thought. The variety of models available can be overwhelming. It's important to consider specific application needs. Always reflect on what works best for your situation. The benefits of these pumps are clear, yet careful evaluation is essential.

When considering pumps for industrial applications, Shield Pumps stand out due to their essential features. One key aspect is their robust construction. They can handle harsh environments with reliability. The materials used are often resistant to corrosion and damage. This ensures a longer operational life, reducing the need for frequent replacements.

Another significant feature is their efficiency. Shield Pumps are designed to minimize energy consumption. This can lead to substantial cost savings over time. Additionally, they deliver consistent performance, even under varying pressures. This reliability is crucial in maintaining process stability across industrial systems.

However, not all users fully leverage these benefits. Some might overlook the importance of regular maintenance. Proper upkeep enhances pump lifespan and performance. Others may struggle with understanding the technical specifications. Investing time in learning will help users make informed decisions. Adopting a proactive approach can yield better results in industrial operations.

| Feature | Description | Benefits |

|---|---|---|

| Durability | Designed to withstand harsh industrial environments. | Reduces downtime and maintenance costs. |

| Efficiency | Engineered for optimal performance with minimal energy consumption. | Lower operational costs and higher productivity. |

| Versatility | Suitable for various fluids and applications. | Flexibility to adapt to different industrial needs. |

| Ease of Maintenance | Designed for quick and easy maintenance without special tools. | Reduces maintenance time and costs. |

| Customizability | Available in various configurations to meet specific application requirements. | Ensures optimal performance for unique operational challenges. |

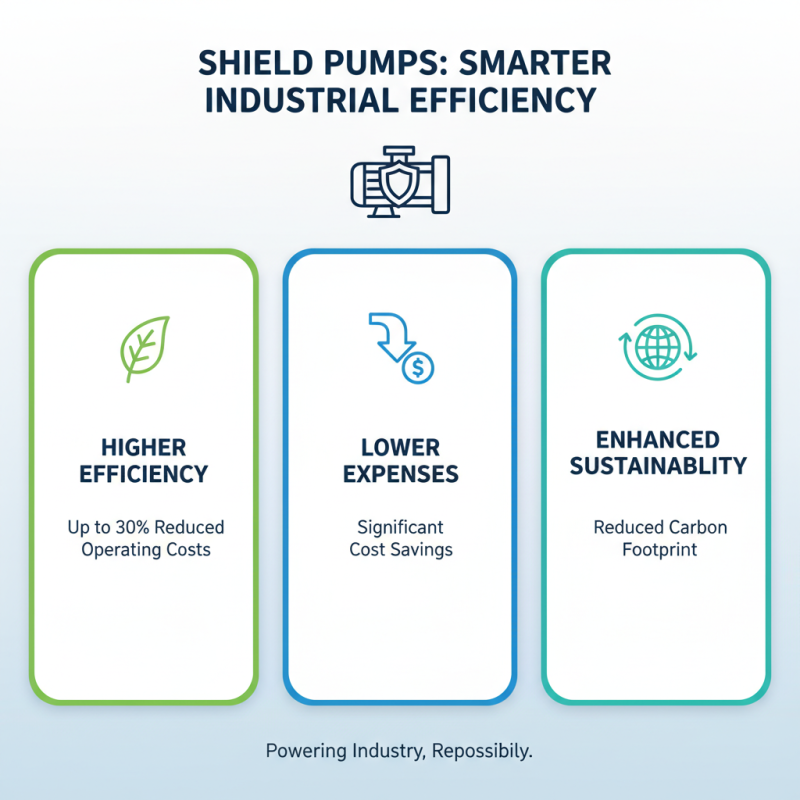

When it comes to industrial pumps, choosing the right one can significantly impact efficiency. Shield pumps offer numerous advantages over competitors. For instance, they frequently exhibit higher energy efficiency ratings. Reports indicate that energy-efficient pumps can reduce operating costs by up to 30%. This is crucial for companies looking to lower expenses and enhance sustainability.

Using shield pumps can result in fewer maintenance issues. Their robust design minimizes wear and tear. According to industry studies, equipment longevity can increase by as much as 25% when using high-quality pumps. This not only saves costs on replacements but also ensures continuous operations.

Tips: Regular maintenance checks can further extend pump life. Monitor the performance and look for any unusual vibrations. Additionally, ensure proper installation to prevent issues down the line. Investing in training for your staff can also pay dividends in proper handling and troubleshooting.

Shield pumps are increasingly used across multiple industries. Their efficiency and durability make them a preferred choice for various applications. In the oil and gas sector, for instance, pumping systems often deal with corrosive materials. A recent industry report indicates that over 30% of operational costs come from fluid handling. The right pump can significantly reduce these expenses.

In chemical processing, the reliability of a pump is crucial. These pumps handle hazardous materials. A small failure can lead to safety issues and financial loss. Statistics show that 25% of chemical plants face unscheduled downtime due to equipment failure. Choosing a robust pumping solution can help mitigate this risk.

Water treatment facilities also rely on shield pumps. They support the distribution and filtration processes. According to industry analysts, effective pumping systems can improve water delivery efficiencies by up to 40%. However, not all facilities utilize the best technology. Regular maintenance and upgrades are often neglected, leading to suboptimal performance. Reflecting on these challenges can guide better investment strategies in pump technology.

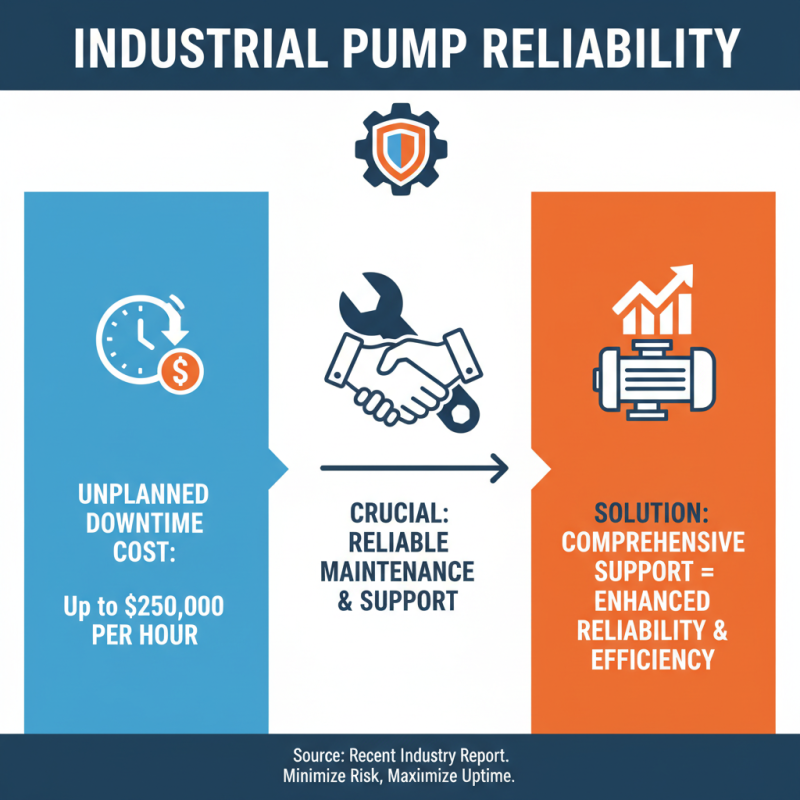

When selecting pumps for industrial applications, maintenance and support are crucial. A recent industry report noted that machine downtime can cost companies up to $250,000 per hour. This stark figure underscores the need for reliable maintenance services. Choosing a provider that offers comprehensive support can enhance equipment reliability and efficiency.

Shield Pumps offers tailored maintenance plans to minimize unexpected failures. Regular inspections can catch potential issues before they escalate. With predictive maintenance tools, facilities can identify wear-and-tear signs early. A study revealed that predictive maintenance can reduce operational costs by 25-30%. This approach not only lengthens the life of equipment but also ensures continuous productivity.

Support goes beyond just maintenance checks. Effective communication with technical support personnel can clarify issues swiftly. Access to expert knowledge can prevent small problems from becoming significant setbacks. However, some companies may overlook the importance of ongoing training for their staff. Investing in team skills is sometimes neglected but can lead to better overall performance.

When it comes to selecting the right pumps for industrial applications, customer feedback is invaluable. Many users have shared their experiences with the performance of these pumps. They often highlight efficiency and durability. One client noted a significant reduction in downtime due to the reliable operation. Another emphasized how energy savings improved their bottom line.

It's not just about the positive remarks. Some clients faced challenges during initial setup. A few struggled with the installation process. Yet, with support and guidance, they found success. These experiences highlight the importance of customer service in addressing concerns.

Tip: Always prioritize understanding the technical background before installation. This helps avoid complications. Ensure thorough training and familiarize your team with pump specifications.

Moreover, real-world case studies showcase improvements in manufacturing processes. One manufacturer reported smoother operations and less wear on equipment. They attributed this to the pump's consistent performance under varying conditions. These testimonials illustrate the impact of choosing the right equipment for industrial needs.

Tip: Regular feedback loops can enhance pump performance. Encourage your team to share insights and report any issues to improve future operations.