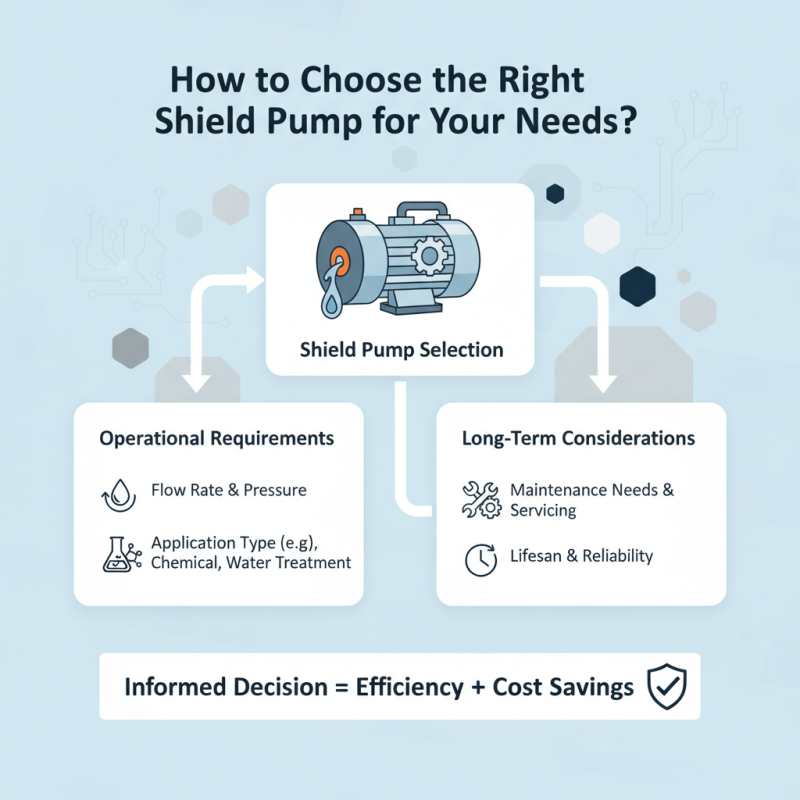

Selecting the right Shield Pump is critical for a variety of industries. According to a recent report by MarketsandMarkets, the global pump market is expected to reach USD 77.07 billion by 2028. This growth highlights the increasing demand for efficient and reliable pumping solutions. However, not every Shield Pump fits every need. It is crucial to consider specific operational requirements.

For example, different applications may require pumps with varying flow rates and pressure ratings. A Shield Pump designed for chemical processing may differ significantly from one intended for water treatment. This nuance often leads to confusion. A poorly chosen pump can lead to inefficiencies and increased operational costs. Therefore, understanding your unique requirements is essential.

Furthermore, many buyers tend to overlook maintenance needs. Regular servicing impacts pump performance and lifespan. Ignoring these factors can result in serious breakdowns. Choosing the right Shield Pump involves a careful evaluation of both performance specifications and maintenance needs. Making informed decisions now can save time and resources in the long run.

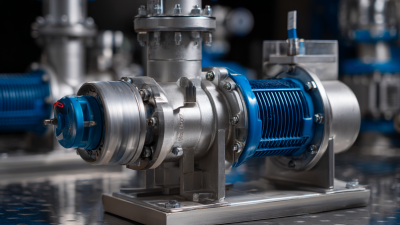

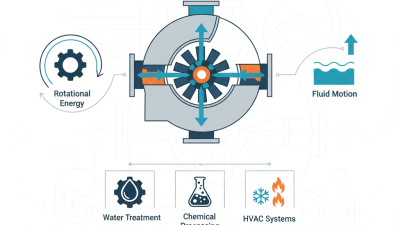

Selecting the right shield pump begins with understanding the various types available. Different applications demand specific features. For instance, centrifugal shield pumps excel in high flow rates. They handle large volumes efficiently. These pumps are commonly used in water treatment and chemical processing industries.

Another popular type is the diaphragm shield pump. This kind is ideal for handling viscous fluids. Its unique design allows it to move slurries and abrasive substances effectively. However, users sometimes face challenges with diaphragm wear. Regular maintenance is crucial to avoid pump failure.

Choosing the right pump also depends on material compatibility. Some fluids can corrode certain materials. This can lead to costly repairs or replacements. Always consider the fluid's chemical composition. A little research can save significant headaches later. A mismatched pump can underperform. Ensure you thoroughly evaluate your needs.

| Pump Type | Application | Flow Rate (l/min) | Pressure Range (bar) | Efficiency (%) |

|---|---|---|---|---|

| Centrifugal Pump | Water Circulation | 500 | 3-10 | 85 |

| Diaphragm Pump | Chemical Transfer | 200 | 1-5 | 90 |

| Gear Pump | Oil Transfer | 150 | 5-20 | 88 |

| Piston Pump | High-Pressure Applications | 100 | 10-100 | 82 |

| Peristaltic Pump | Pharmaceuticals | 350 | 0.1-5 | 92 |

When choosing the right shield pump, various factors come into play. The pump's capacity is critical. A pump with too low a capacity may not meet your operational needs. Conversely, a pump with excessive capacity can lead to unnecessary energy consumption. Research by the International Energy Agency (IEA) shows that pumps account for about 20% of global electricity use. This highlights the importance of matching pump capacity to your application.

Material compatibility is another vital factor. Different fluids interact uniquely with materials. For example, corrosive fluids may require pumps made from specialized alloys or plastics. According to the Fluid Sealing Association, improper material selection can result in costly failures. Users often underestimate this risk, leading to unexpected downtime.

Moreover, always consider the pump's efficiency. A highly efficient pump can save significant operational costs. The U.S. Department of Energy reports that improving pump efficiency can reduce energy costs by up to 30%. However, many operators overlook maintenance and monitoring, which can diminish efficiency over time. Regular assessments and adjustments are necessary. This is an area where many industries fall short. Prioritizing efficiency and compatibility can prevent long-term issues and enhance reliability in operations.

This bar chart illustrates key factors to consider when selecting a shield pump, such as flow rate, maximum pressure, power consumption, noise level, and weight. Understanding these characteristics can help you make an informed decision based on your specific requirements.

When selecting a shield pump, assessing flow rates and pressure requirements must be a priority. Flow rate is typically measured in gallons per minute (GPM) or liters per minute (LPM). For many applications, a flow rate of 20-150 GPM is common. Yet, some systems demand much higher rates. A mismatch here can lead to inefficiencies. It’s crucial to align these metrics with the specific needs of your system.

Pressure is just as vital. Many systems operate efficiently at pressures ranging from 30 to 100 PSI. If the pump does not meet the required pressure, it can lead to system failures. Studies indicate that over 30% of application failures stem from improper pressure settings. These figures highlight the importance of careful evaluation. One must analyze both the static and dynamic conditions of the system carefully.

In addition, it's essential to consider the pump's ability to handle varying flow rates. Not all applications maintain a consistent demand. Many systems experience fluctuations that can affect performance. Thus, a pump designed for a narrow range may struggle. It’s always necessary to anticipate potential changes in demand. This proactive approach can prevent costly downtime and ensure optimal performance.

Choosing the right material for shield pumps is crucial. Many factors affect performance. The environment plays a key role. For instance, corrosive chemicals can degrade materials quickly. Therefore, compatibility with the fluid being pumped is important.

Durability is not just about strength. It also involves resistance to wear and tear. Some materials may withstand high pressures but fail under constant use. It’s vital to assess the operational environment. For example, extreme temperatures can alter material properties. Evaluate whether the pump will face constant flow or intermittent use.

Researching material options is essential. Some people may overlook this aspect. A poor choice could lead to increased maintenance costs. Consider the long-term impact. Ask questions about the materials’ lifespan. Sometimes, the shiny new option may not be the best fit. Assess both initial costs and durability over time. Test different materials when possible. Your decision matters.

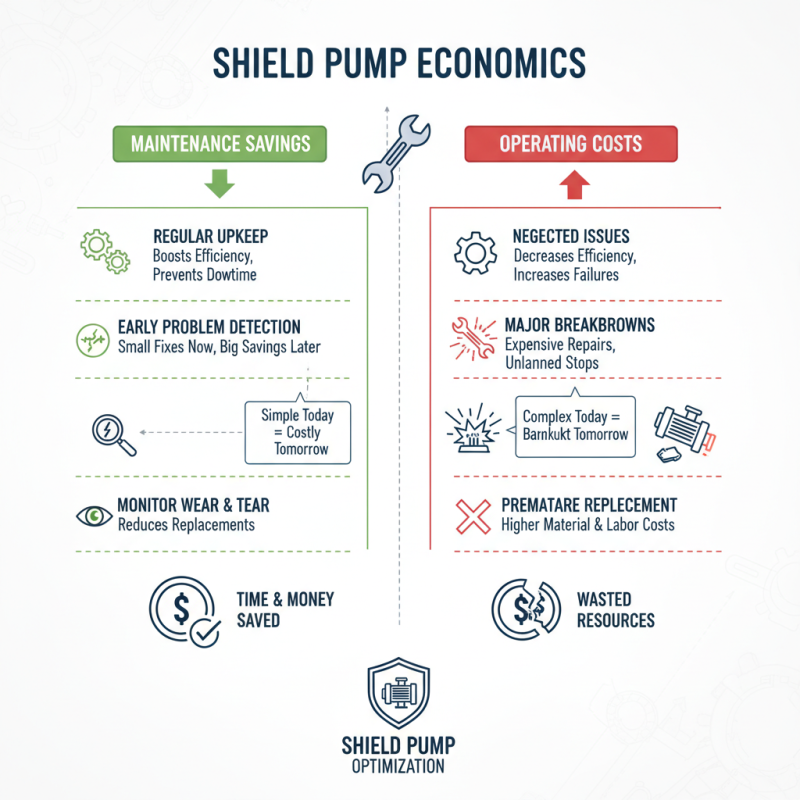

When considering shield pumps, maintenance and operating costs are crucial. Regular upkeep is vital for efficiency. Neglecting small problems can lead to bigger issues. A simple fix today can prevent costly repairs tomorrow. Keep an eye on wear and tear. This can save time and money in the long run.

Operating costs vary by usage. Monitor energy consumption closely. It helps to understand how often the pump is in operation. Not all pumps are created equal in efficiency. Sometimes, a more expensive model could reduce costs over time through savings on energy. Additionally, consider the environment where the pump operates. Harsh conditions can lead to more frequent repairs.

It's easy to overlook the need for proper training in maintenance tasks. Staff should be knowledgeable about basic troubleshooting. This can significantly reduce downtime. Communication is also key. Discuss any issues with your team. Sometimes, the solution might be simple, but it requires collective insight. Yet, some teams might hesitate to share problems, missing out on simple fixes. Balancing costs and performance requires ongoing assessment and adaptation.