In the dynamic world of construction, the importance of efficient material transportation cannot be overstated. One of the key innovations in this domain is the Concrete Pump, a device that has revolutionized how concrete is delivered to various construction sites. As industry expert John Smith, a renowned civil engineer with over two decades of experience, states, "A Concrete Pump is not just a tool; it's an essential component that ensures that concrete reaches challenging locations swiftly and precisely."

Concrete Pumps come in various types, each tailored to meet specific needs, whether it’s for high-rise buildings, bridges, or intricate architectural designs. By utilizing this equipment, construction professionals can enhance productivity, reduce labor costs, and improve the quality of concrete placement. Additionally, understanding the different types of Concrete Pumps, such as boom pumps and line pumps, equips builders with the knowledge to select the most suitable option for their projects.

As we explore the functionality and applications of Concrete Pumps, it becomes evident that they are not merely mechanical devices, but pivotal instruments that drive the construction industry forward, facilitating innovative design and efficient project execution.

A concrete pump is an essential piece of equipment in the construction industry, designed for transferring liquid concrete through a hose for pouring at a construction site. It enables efficient and precise concrete placement, minimizing the need for manual handling, which can be labor-intensive and time-consuming. According to a report by Allied Market Research, the global concrete pumping market is expected to reach $4.5 billion by 2025, indicating a significant growth driven by the increasing demand for high-rise buildings and infrastructural development around the world.

There are mainly two types of concrete pumps: boom pumps and line pumps. Boom pumps are equipped with a robotic arm that allows for precise placement of concrete in hard-to-reach locations, making them ideal for large-scale projects such as skyscrapers and bridges. On the other hand, line pumps consist of a flexible hose system that allows for easy maneuverability, making them suitable for smaller jobs or areas where access is limited. The choice between these types often depends on the specific requirements of the job site, with factors such as height, distance, and volume of concrete to be placed influencing the decision. As the construction industry continues to evolve, the role of concrete pumps is becoming more critical, enhancing both productivity and safety on job sites.

| Type of Concrete Pump | Description | Common Uses | Advantages |

|---|---|---|---|

| Boom Pump | A pump attached to a multi-section robotic arm that positions concrete with great precision. | High-rise buildings, large foundations, and complex structures. | Fast placement, reduced labor costs, and ability to reach difficult locations. |

| Line Pump | A more portable pump that uses pipes or hoses to transport concrete to the desired location. | Small to medium-sized projects like sidewalks, slabs, and residential foundations. | Cost-effective, versatile, and suitable for tight spots. |

| Trailer Pump | A pump mounted on a trailer that can be towed by a vehicle to different job sites. | Residential and commercial projects that require mobility, such as driveways and patios. | Easily transportable, efficient for small jobs, and minimizes setup time. |

| Truck Mounted Pump | A concrete pump mounted on a truck for easy access and use on construction sites. | Medium to large commercial construction projects, bridge construction. | Quick mobility, capable of reaching various heights, and high capacity. |

Concrete pumps are essential tools in modern construction, enabling the efficient transfer of concrete from the mixer to the desired location. There are several types of concrete pumps, each designed for specific applications and project requirements. The two primary types are line pumps and boom pumps.

Line pumps consist of a series of pipes through which liquid concrete is transported. They are highly versatile, allowing for flexibility in directing concrete to hard-to-reach areas, making them ideal for smaller projects and job sites with limited access. On the other hand, boom pumps are equipped with a robotic arm that can extend and bend, delivering concrete precisely where it's needed. These pumps are typically used for larger construction projects, such as high-rise buildings, where large volumes of concrete must be poured efficiently.

In addition to these main types, there are specialized pumps such as trailer-mounted line pumps and truck-mounted boom pumps. Trailer-mounted pumps are towed to the site and provide a cost-effective solution for remote access applications, while truck-mounted boom pumps offer mobility and speed, allowing high-rise construction teams to work rapidly without additional equipment. Each type of pump serves a unique purpose, contributing to the overall efficiency and effectiveness of construction processes.

Concrete pumps are essential equipment in modern construction, designed to transport liquid concrete from the mixer to the desired location efficiently. There are two primary types of concrete pumps: boom pumps and line pumps. Boom pumps are mounted on trucks and offer the flexibility to extend and maneuver the boom for easy placement at height or over obstacles, while line pumps use flexible hoses to convey concrete through pipelines, making them ideal for smaller jobs and tighter spaces.

The operation of concrete pumps is critical in optimizing the workflow on construction sites. According to a report by the American Concrete Pumping Association (ACPA), the use of concrete pumps can reduce labor costs by up to 40%, significantly increasing construction efficiency. These machines are equipped with a series of hydraulic cylinders that push the concrete through the pump and into the delivery system. Subsequently, the concrete is either poured directly into forms or transferred to a designated area. By minimizing the need for manual handling of heavy materials, concrete pumps enhance safety and speed up project timelines, which is especially important in large-scale developments where downtime can result in considerable financial losses.

As construction projects continue to grow in scale and complexity, the reliance on concrete pumps is projected to increase. The global concrete pump market is expected to expand significantly, with estimates suggesting growth rates of around 5% annually through the next decade. This trend underscores the pivotal role concrete pumps play in driving efficiency and productivity in the construction industry, ensuring that projects are completed on time and within budget.

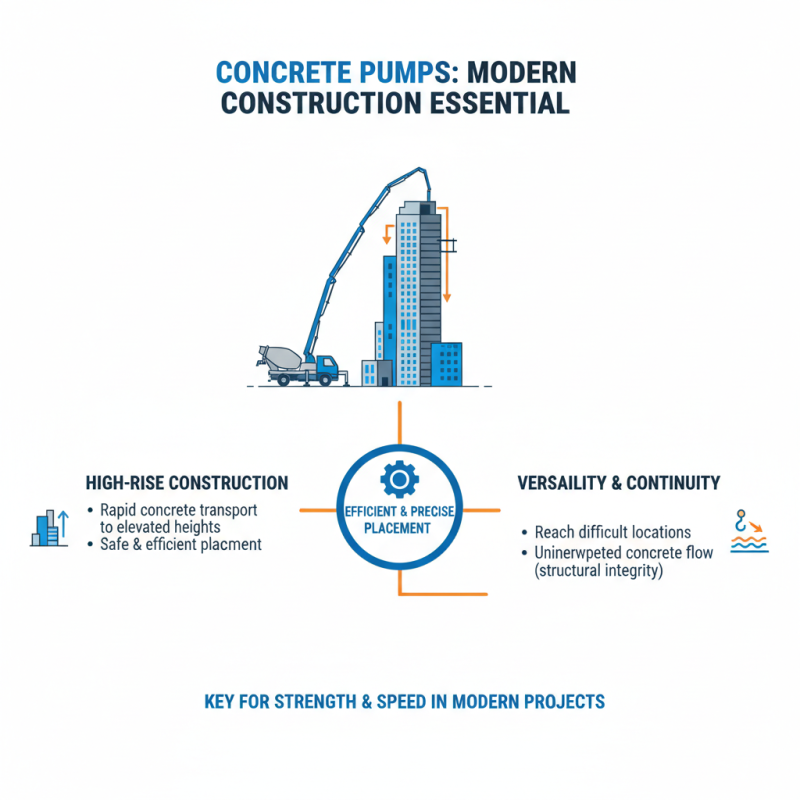

Concrete pumps play a pivotal role in modern construction projects, allowing for the efficient and precise placement of concrete in various applications. One primary use of concrete pumps is in high-rise building construction. In these projects, the ability to transport concrete to elevated heights quickly and safely is crucial. The versatility of concrete pumps makes them ideal for reaching difficult locations and ensuring that the concrete is delivered in a continuous flow, which is essential for maintaining the integrity and strength of the structure.

Another significant application of concrete pumps is in infrastructure projects, such as bridges and roads. These pumps facilitate the pouring of concrete in areas that are otherwise hard to access or require meticulous placement for quality and safety standards. Additionally, in residential construction, concrete pumps can be used for foundations, slabs, and walls, streamlining the process and reducing labor costs. Their adaptability not only optimizes construction timelines but also enhances the overall quality of the concrete work, making them indispensable tools in the building industry.

Concrete pumps are essential equipment in the construction industry, significantly enhancing the efficiency of concrete placement. The benefits of using concrete pumps are manifold, as they facilitate the rapid delivery of concrete to hard-to-reach areas, thereby reducing labor costs and enhancing productivity. According to a report by the American Concrete Institute, projects utilizing concrete pumps can see a reduction in time spent on concrete pouring by up to 30%, allowing construction teams to adhere to stringent schedules.

Moreover, concrete pumps offer improved safety and quality control on job sites. By minimizing the manual handling of concrete, they reduce the risk of accidents associated with traditional pouring methods. The National Ready Mixed Concrete Association reported that using concrete pumps can lead to a significant decrease in material wastage—up to 10%. This not only cuts down on costs but also aligns with sustainable construction practices by optimizing resource use.

Additionally, for large-scale projects, such as high-rise buildings or infrastructures, concrete pumps provide the necessary power to transport concrete over long distances and heights without compromising the mix quality. According to a study published in the Journal of Construction Engineering and Management, construction projects employing concrete pumps demonstrate an average increase in pouring precision, which is crucial for structural integrity and longevity. As the construction industry continues to evolve, the adoption of concrete pumps is expected to grow, driven by their numerous advantages in efficiency, safety, and sustainability.