In the realm of water supply systems, the importance of reliable and efficient mechanisms cannot be overstated. One technological advancement that has significantly improved water extraction is the Deep Well Pump. According to renowned industry expert Dr. Emily Carter, "A Deep Well Pump is not just a tool; it is the lifeline for communities that rely on groundwater sources." This underscores the critical role deep well pumps play in ensuring sustainable water supply, particularly in areas where surface water is scarce.

The operation of a Deep Well Pump involves intricate engineering that allows it to draw water from depths often exceeding hundreds of feet. Understanding how these systems work enables stakeholders—from engineers to policymakers—to implement the best solutions for water management. As cities and rural areas alike grapple with water scarcity and quality issues, the effectiveness of Deep Well Pumps in meeting these challenges becomes ever more relevant. Through this exploration of their functionality and significance, we gain insight into the essential contributions of Deep Well Pumps in our evolving water supply infrastructure.

Deep well pumps are crucial components in water supply systems, designed to extract groundwater from deep underground sources, typically ranging from 25 to over 1,000 feet deep. These pumps utilize a motor-driven mechanism to lift water to the surface, making them ideal for agricultural, municipal, and industrial applications where surface water sources are insufficient or unavailable. According to the American Water Works Association (AWWA), approximately 15% of the nation’s drinking water supply is derived from groundwater, highlighting the pivotal role deep well pumps play in ensuring reliable water access.

The primary purpose of deep well pumps is not only to provide a sustainable source of water but also to maintain water quality and system efficiency. Efficiency ratings can vary, with high-quality deep well pumps achieving more than 80% efficiency in converting electrical energy to hydraulic energy. This capability helps reduce operational costs and energy consumption, which is increasingly important in the context of rising energy prices and environmental sustainability. Furthermore, proper installation and maintenance of these pumps are essential, as studies show that poorly maintained pumps can lead to significant declines in water production and increase the risk of contaminating the water supply. Such statistics underscore the necessity of deep well pumps in meeting the growing demand for clean water.

| Feature | Description |

|---|---|

| Definition | A deep well pump is a type of pump used for extracting water from deep underground sources. |

| Purpose | To provide a reliable source of water for agricultural, residential, and industrial uses. |

| Operation | Operates by using a motor to drive a pump that pulls water through a pipe system from deep aquifers. |

| Types | Submersible pumps and jet pumps are the two main types used for deep well applications. |

| Components | Key components include the pump, motor, well casing, and discharge piping. |

| Efficiency | Deep well pumps are designed for high efficiency, particularly in energy consumption and water delivery. |

| Maintenance | Regular maintenance is required to ensure optimal performance and longevity of the pump. |

Deep well pumps are essential components of water supply systems, designed to draw water from depths that conventional pumps cannot reach. Typically used in agricultural, municipal, and residential applications, these pumps operate efficiently by utilizing a series of components that work in unison to transport water from underground aquifers to the surface.

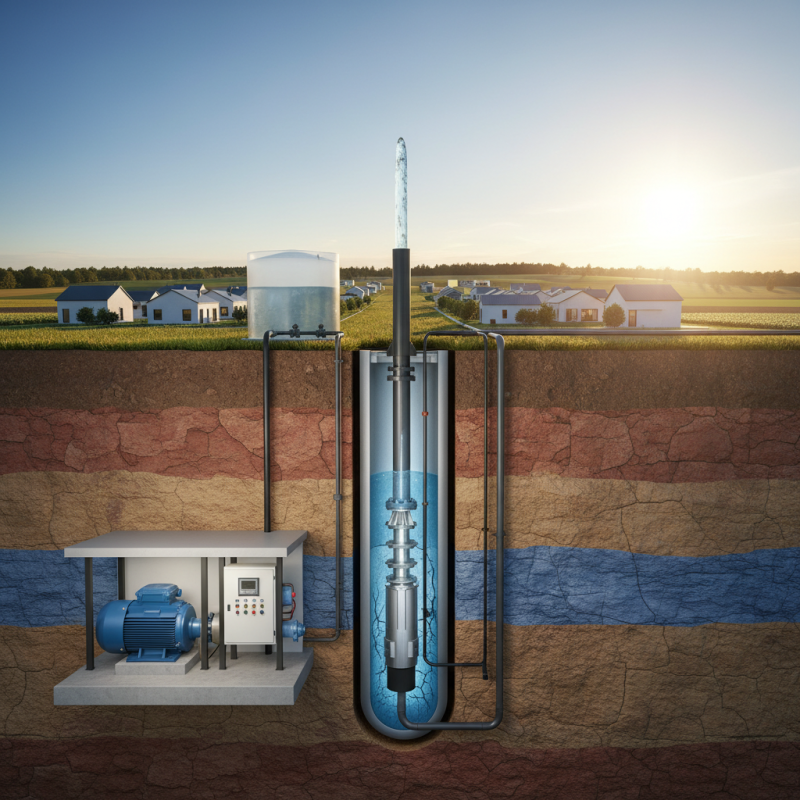

The primary components of a deep well pump include the motor, pump bowl, and impellers. The motor, often located above ground, powers the pump and can vary in horsepower depending on the depth of the well and the volume of water required. The pump bowl houses the impellers, which are critical for moving water through the pump. According to the Water Systems Council, deep well pumps can operate at depths of over 25 feet and are capable of delivering flow rates exceeding 100 gallons per minute. Additionally, submersible models are often used for deeper applications, as they can efficiently function below the water level.

Other notable components include the casing and discharge head. The casing provides structural support and houses the pump mechanics, while the discharge head facilitates the ejection of water from the pump system. Proper maintenance of these components is vital; the American Water Works Association highlights that regular inspections can extend the lifespan of deep well pumps, ensuring dependable water supply in various applications. Through a careful combination of these components, deep well pumps effectively contribute to sustainable water management practices, especially in regions facing water scarcity.

Deep well pumps play a crucial role in water supply systems, specifically designed to extract groundwater from deep underground sources. The mechanism of action for these pumps can be understood through their structure and operation. Typically, a deep well pump consists of a motor, pump bowl assembly, column pipe, and discharge head. The motor, located above ground, powers the pump which is submerged in the water well. This setup allows the pump to reach depths that standard pumps cannot, often exceeding several hundred feet.

The operation begins when the motor engages, driving an impeller within the pump bowl assembly. This impeller creates a flow of water by spinning rapidly, generating centrifugal force that pushes water upwards through the column pipe. As water moves up the column, pressure is increased, allowing it to reach the discharge head at the surface. At this point, the water can be directed to various applications, such as irrigation systems or household supply. The efficiency of deep well pumps is enhanced by multi-stage designs, where multiple impellers work sequentially to elevate water from greater depths, ensuring a consistent supply while minimizing energy consumption.

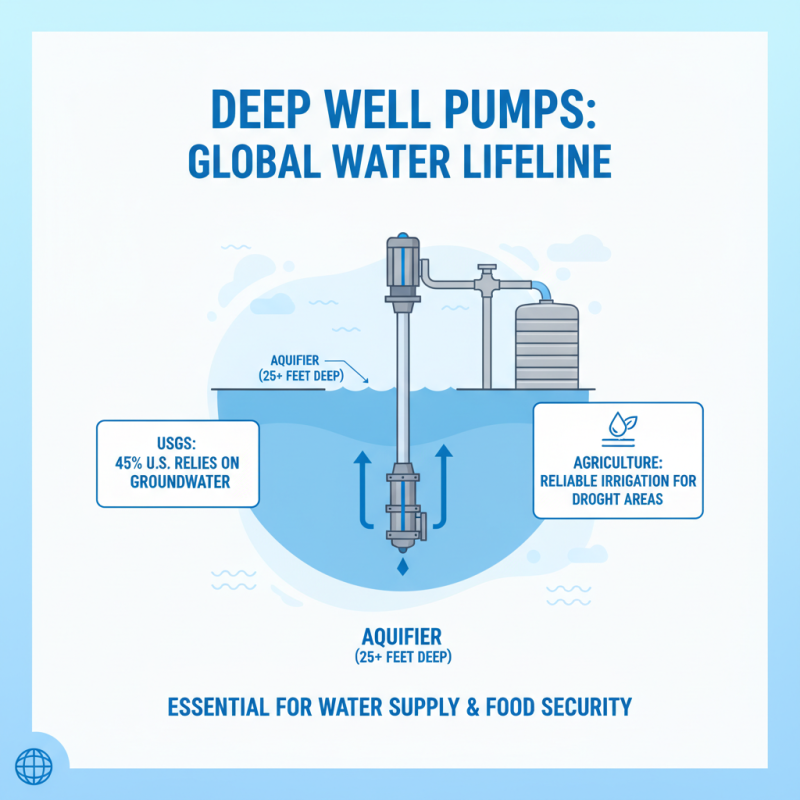

Deep well pumps are essential components of water supply systems, especially in areas where surface water is scarce. They are designed to extract water from deep underground aquifers, typically at depths exceeding 25 feet. According to the U.S. Geological Survey, approximately 45% of the population relies on groundwater as their primary source of drinking water, emphasizing the importance of effective deep well pumping systems. These pumps are particularly advantageous in agricultural applications, providing reliable irrigation solutions, especially in drought-prone regions where surface water may run low.

One significant advantage of deep well pumps is their ability to operate in various challenging environments. They can function efficiently in rocky terrains and are capable of lifting water from substantial depths, ensuring that consistent water supply is maintained even during dry spells. Moreover, deep well pumps tend to have higher efficiency rates compared to shallower pumps, reducing energy consumption and operating costs. A report by the National Ground Water Association indicates that properly maintained deep well systems can save users up to 20% on energy bills compared to less efficient pumping systems.

Tips: When selecting a deep well pump, consider the depth of your well and the water demand for your specific application. Regular maintenance is crucial; ensure check-ups and servicing are performed at least once a year to extend the pump's lifespan and efficiency. Proper sizing of the pump to match your water needs can also prevent unnecessary wear and tear.

Deep well pumps are crucial components in water supply systems, operating at depths where traditional pumps cannot. To ensure their long-term efficiency, regular maintenance and troubleshooting are essential. Routine inspections should focus on the pump's motor, bearings, and check valves, as these parts can wear out due to continuous operation. According to a report from the American Water Works Association, proper maintenance can extend the lifespan of deep well pumps by 20-30%, thereby reducing the cost of replacements and downtime.

Issues such as decreased water flow and unusual noises often signal underlying problems with deep well pumps. The National Ground Water Association suggests implementing a preventative maintenance schedule that includes monitoring parameters such as power usage and vibration levels. These metrics can help detect problems before they escalate. If flow rates drop unexpectedly, sediment buildup or a malfunctioning depth switch may be to blame. Addressing these issues promptly not only enhances the system's efficiency but also safeguards the water supply's reliability, which is critical in agricultural and municipal applications alike.