In today's industrial landscape, optimizing energy efficiency is a critical goal for organizations striving to reduce operational costs and minimize their environmental impact. One of the pivotal components in achieving this efficiency is the Turbine Pump, a device designed to move fluids by converting mechanical energy into hydraulic energy. Understanding the efficiency of Turbine Pumps is essential for industries relying on fluid transfer processes, as these pumps often play a significant role in overall system performance.

This article delves into the operational principles and advantages of Turbine Pumps, shedding light on their role in enhancing energy savings across various industrial applications. By examining factors such as design, performance metrics, and maintenance practices, we aim to provide a comprehensive guide for industries seeking to maximize the benefits of Turbine Pumps in their operations.

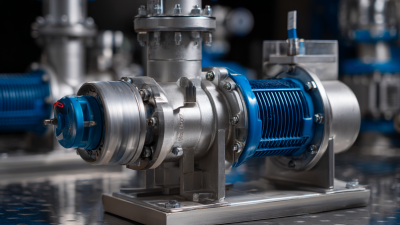

In industrial settings, turbine pumps play a crucial role in a variety of applications, including water supply, chemical processing, and oil recovery. The main types of turbine pumps used in these industries include

vertical turbine pumps,

horizontal turbine pumps,

and

submersible turbine pumps.

Each type is designed to handle specific fluid characteristics and operational conditions, making them essential for efficiency and reliability in demanding environments.

Vertical turbine pumps are particularly effective for applications requiring high lift over long distances, often employed in municipal water supply systems.

Horizontal turbine pumps, on the other hand, excel in situations where space is limited and are commonly used in irrigation and drainage systems.

Submersible turbine pumps are designed to be submerged in the fluid they are pumping, making them ideal for deep well applications.

Tips: When selecting a turbine pump for industrial use, consider the pump's head, flow rate, and efficiency rating.

Regular maintenance is also vital to ensure optimal performance and longevity.

Additionally, matching the pump type to the specific application can lead to significant energy savings and reduced operational costs over time.

Turbine pumps play a crucial role in various industrial applications, and their efficiency can significantly influence operational costs and energy consumption. Several factors contribute to the efficiency of these pumps, including the design of the pump impellers, the quality of materials used, and operational conditions like flow rate and suction head. A well-designed impeller can lead to higher hydraulic efficiency, minimizing energy wastage while optimizing performance.

**Tips:** To enhance the efficiency of turbine pumps, consider regularly maintaining and inspecting the equipment to identify any wear or misalignment. Additionally, ensuring that the pump operates within its specified flow range will help maintain optimal efficiency and reduce energy costs.

Environmental conditions, such as temperature and fluid viscosity, also affect pump efficiency. High temperatures can reduce the density of the fluid and increase the power required to move it, while higher viscosities can lead to greater friction losses. Selecting the right turbine pump for the specific application and conditions can greatly mitigate these issues.

**Tips:** Engage with experts to perform a comprehensive analysis of your pumping system to identify inefficiencies. Upgrading to advanced pump designs or materials can provide long-term energy savings, leading to a more sustainable operation.

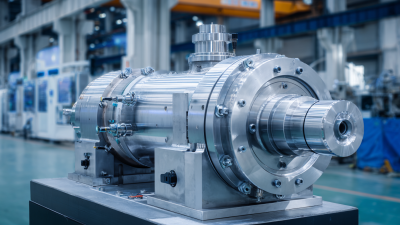

Turbine pumps have gained significant attention in industrial applications due to their unique advantages over other pump types. According to the Hydraulic Institute’s report, turbine pumps are known for their high efficiency and long operational life, which can lead to substantial energy savings. These pumps typically achieve efficiencies of around 85-90%, outperforming many centrifugal pumps that often range between 60-80% efficiency. This difference in performance is particularly crucial in operations where energy costs represent a significant portion of overall expenses.

Turbine pumps have gained significant attention in industrial applications due to their unique advantages over other pump types. According to the Hydraulic Institute’s report, turbine pumps are known for their high efficiency and long operational life, which can lead to substantial energy savings. These pumps typically achieve efficiencies of around 85-90%, outperforming many centrifugal pumps that often range between 60-80% efficiency. This difference in performance is particularly crucial in operations where energy costs represent a significant portion of overall expenses.

When comparing turbine pumps with positive displacement pumps, it's essential to note that while positive displacement pumps can deliver high-pressure outputs, they often come with higher maintenance costs and lower energy efficiency. Industry studies indicate that the total cost of ownership for turbine pumps is generally lower over time due to their reliability and lower energy consumption. The U.S. Department of Energy’s Energy Efficiency Program highlights that implementing more efficient pumping solutions can reduce energy use in industrial settings by up to 20%, making turbine pumps a preferable choice for industries aiming to enhance their sustainability and reduce operational costs.

Energy efficiency in turbine pump operations plays a crucial role, especially in energy-intensive industries like mining. As mining operations, such as those targeting rare earth elements, become more prevalent, the need for efficient energy use is paramount. Turbine pumps are vital in these environments as they move large volumes of water necessary for various processes, including cooling and slurry transport. By implementing energy-efficient turbine pump designs and strategic practices, mining operations can significantly reduce their energy consumption and costs.

One effective strategy for enhancing the efficiency of turbine pumps is optimizing their operation through advanced monitoring and control systems. These systems allow for real-time adjustments based on operational demands, ensuring that pumps operate at peak efficiency without wasting energy. Additionally, regular maintenance and upgrades to more efficient models can further enhance performance. By prioritizing energy efficiency in turbine pump operations, industries not only contribute to sustainability efforts but also align with broader climate action goals to achieve net zero emissions by 2050. The integration of such efficient practices is vital in transitioning towards a more electrified and sustainable future for industrial applications.

The implementation of turbine pumps across various industrial applications has demonstrated significant energy savings, particularly in the context of energy efficiency initiatives supported by energy services. Between 2024 and 2025, numerous projects focusing on fleet optimization and renewable energy integration are set to leverage the capabilities of regenerative turbine pumps. These pumps not only enhance operational efficiency but also contribute to substantial reductions in energy consumption, aligning with global sustainability goals.

Tip: When considering turbine pump systems for your industrial applications, evaluate the potential for energy savings by conducting a comparative analysis of existing systems versus new turbine pump solutions.

Moreover, the regenerative turbine pump market, projected to grow from USD 271.1 million in 2025 to USD 548.5 million by 2035, indicates a burgeoning interest in energy-efficient technologies. As industries increasingly adopt these pumps, they can expect improvements in performance and energy economy, particularly in challenging environments like arid regions.

Tip: Stay informed about advancements in machine learning frameworks that analyze water and energy efficiency. Implementing such technologies can significantly optimize resource management strategies, especially in areas facing severe water scarcity.