In the ever-evolving landscape of construction and excavation, the significance of reliable tools cannot be overstated. One such essential tool is the Excavation Water Pump, which plays a critical role in ensuring smooth and efficient water removal during various projects. As industry expert John Carter, a leading voice in the construction equipment sector, aptly states, “The right Excavation Water Pump can mean the difference between a successful job site and a costly delay.” His insights echo the sentiments of many professionals who rely on this equipment every day to optimize their operations.

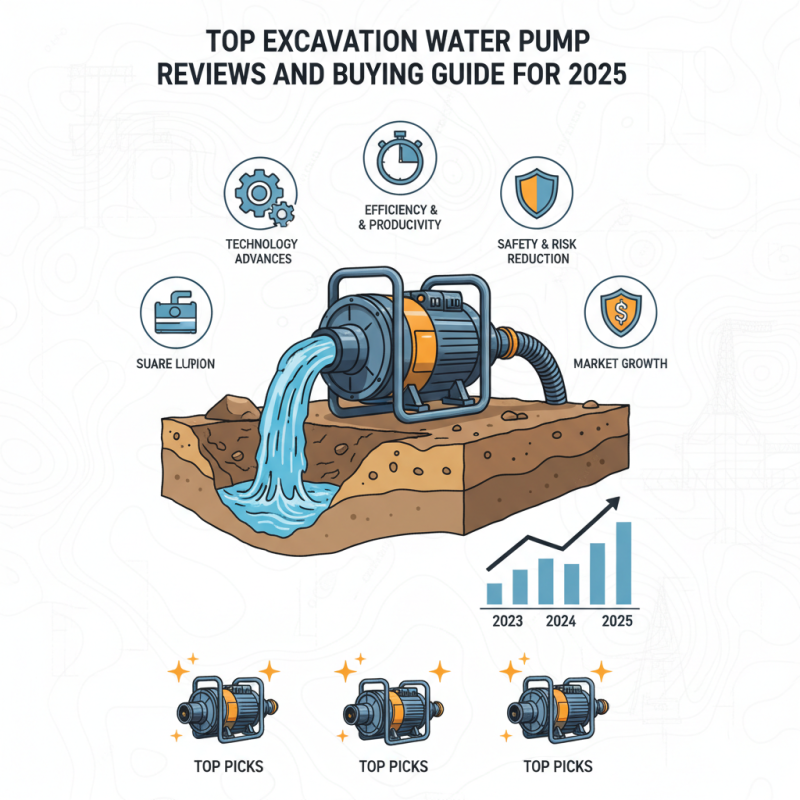

As we approach 2025, the market for Excavation Water Pumps continues to grow, driven by advances in technology and an increasing demand for efficient water management solutions. The right pump not only enhances productivity but also minimizes the risks associated with water accumulation, ensuring that construction timelines are met and safety is maintained. This guide aims to provide a comprehensive overview of the best Excavation Water Pumps available, highlighting key features, reviews, and practical recommendations to help professionals and enthusiasts make informed purchasing decisions in this pivotal segment of the industry.

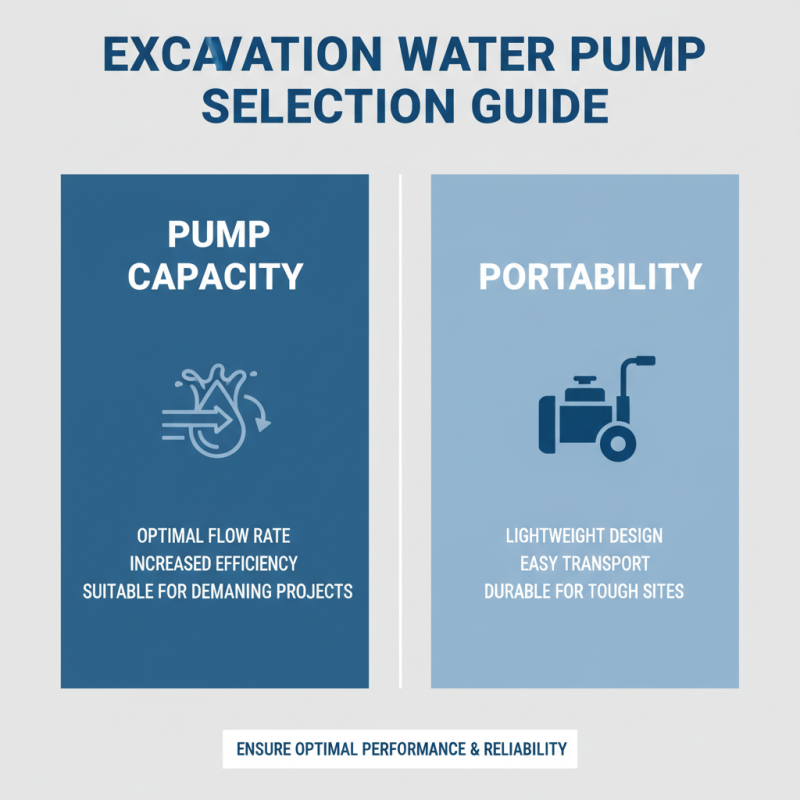

When choosing an excavation water pump, several key features should be considered to ensure optimal performance and reliability. First, pump capacity is crucial; selecting a pump with the right flow rate for your specific needs will enhance efficiency, especially in demanding excavation projects. Portability is another essential aspect, as many jobs require pumps to be easily moved from site to site. Look for lightweight designs with durable build quality that can withstand tough conditions.

Additionally, consider the type of power source that best fits your needs. While electric pumps are ideal for consistent power supply, gas-powered variants offer more mobility, especially in remote locations. The design of the pump—such as its intake and discharge fittings—affects ease of setup and maintenance, making compatibility with your existing equipment an important consideration. Finally, reliability and manufacturer support can significantly affect long-term satisfaction, so opting for brands with a strong reputation can provide peace of mind in your investment.

When considering excavation water pumps, it's essential to understand the various types available and their respective pros and cons. Centrifugal pumps, for instance, are known for their efficiency and reliability, making them ideal for large-scale excavation projects. Their capability to handle large volumes of water, often up to several thousand gallons per hour, positions them as a leading choice for significant drainage operations. However, they may struggle with slurry or debris-laden water, which could lead to increased wear over time.

On the other hand, submersible pumps offer a distinct advantage when working in tight or deep spaces. These pumps can operate fully submerged in water, making them effective for excavation where the water table is high. Their ability to pump dirty water makes them suitable for various applications, but they can be more complex to maintain compared to their surface counterparts. According to recent industry reports, choosing the right type of water pump can influence the overall efficiency of excavation projects, with the right models helping to reduce operational downtime by up to 30%. Understanding these variations is critical for making informed purchasing decisions and optimizing performance in excavation tasks.

When selecting an excavation water pump, understanding the appropriate size and power requirements is crucial for optimal performance. According to the U.S. Department of Energy, pumps that match the required flow rate to the specific job can reduce energy usage by as much as 20%. Flow rate, measured in gallons per minute (GPM), is often the first metric to consider. For instance, a typical excavation site may require a pump with a capacity of 50 GPM to effectively handle runoff and prevent water accumulation, ensuring that project timelines are not hindered by excessive water.

Power requirements go hand-in-hand with pump size; the pump's horsepower (HP) must align with the volume of water being moved against gravitational and frictional forces. A report by the Hydraulic Institute suggests that choosing a pump that is underpowered can lead to frequent breakdowns, while over-specifying can waste energy. Therefore, before purchasing, it's advisable to evaluate the total dynamic head (TDH) necessary for lifting water. By aligning the pump's HP with the calculated TDH, users can achieve not only efficiency but also longevity in their equipment, ultimately resulting in a more cost-effective solution for their excavation projects.

To achieve optimal performance and longevity of your excavation water pump, regular maintenance is essential. Start by ensuring that the pump is clean and free of debris. Before each use, inspect the intake screen and discharge line for any blockages that may impede water flow. Clearing away dirt and sediment will enhance efficiency and prevent premature wear on the pump components.

In addition to routine cleaning, it’s crucial to check the pump’s oil levels and replace them as recommended by the manufacturer. Regularly inspect the seals and gaskets for any signs of wear or leakage; replacing worn parts promptly can save you from costly repairs down the line. Lastly, if your pump operates in harsh environments, consider investing in protective covers or enclosures to shield it from extreme weather, which can further extend its lifespan and reliability.

| Pump Model | Max Flow Rate (GPM) | Max Head (Feet) | Weight (lbs) | Price ($) | Durability Rating (1-10) | Noise Level (dB) | Maintenance Tips |

|---|---|---|---|---|---|---|---|

| Model A | 150 | 30 | 45 | 300 | 9 | 75 | Regular oil changes, check seals weekly |

| Model B | 120 | 28 | 50 | 250 | 8 | 80 | Clean filters monthly, inspect hoses |

| Model C | 180 | 32 | 55 | 320 | 10 | 70 | Check impeller regularly, winterize before freezing |

| Model D | 160 | 30 | 65 | 280 | 7 | 85 | Lubricate bearings, check electrical connections |

| Model E | 140 | 25 | 40 | 260 | 9 | 78 | Inspect gaskets, check for leaks |

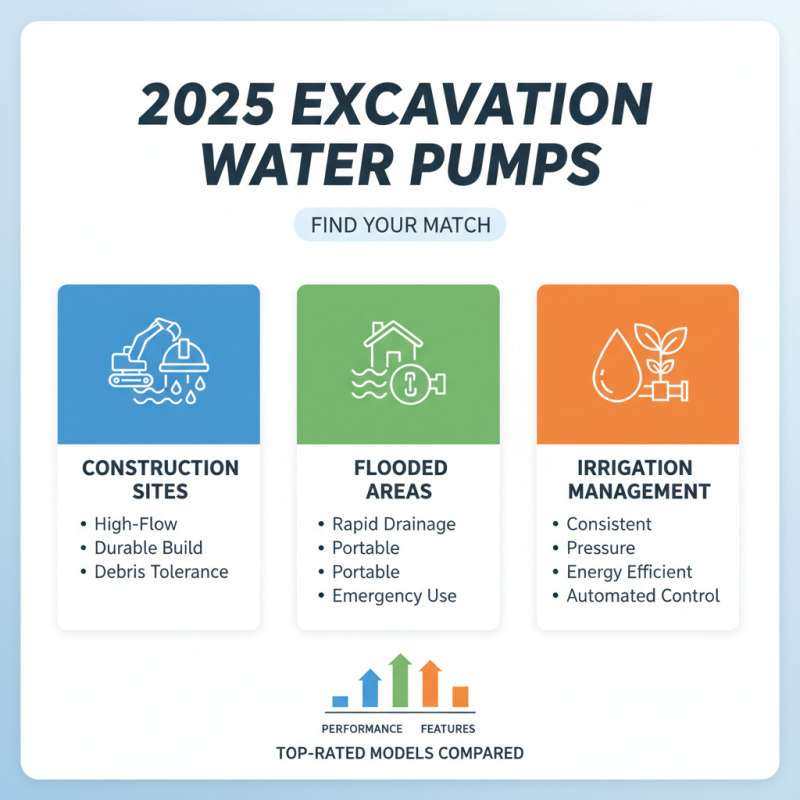

When it comes to excavation water pumps for 2025, making an informed choice is crucial for efficient performance and reliability. Our comprehensive reviews highlight top-rated models suited for various needs, whether you are handling construction sites, draining flooded areas, or managing irrigation. Each pump's features, specifications, and performance ratings are compared to ensure you find the right match for your projects.

Tips for selecting the ideal excavation water pump include considering the pump's capacity, the type of fluid it can handle, and its portability. A pump with a higher flow rate will save time during large-scale operations, while lightweight models are more convenient for transport. Additionally, look for durable construction materials to ensure longevity, especially if you plan to use the pump in harsh conditions.

Another key aspect is energy efficiency. Opting for pumps with lower power consumption can lead to significant savings, especially for prolonged use. Moreover, familiarize yourself with user reviews and warranties offered by manufacturers to gauge the reliability and support you can expect after your purchase. Investing time in research will pay off when it comes to selecting a reliable partner for your excavation needs.