In today's rapidly evolving energy landscape, efficient energy management has emerged as a critical focus for industries seeking sustainable practices and cost savings. The integration of technology plays a crucial role in achieving these goals, with the Remote Monitoring Pump standing out as an essential tool for effective oversight. According to a report by the International Energy Agency, energy efficiency improvements could potentially reduce global energy demand by 20% by 2040, underscoring the importance of innovative solutions in optimizing energy use.

Remote Monitoring Pumps enable real-time data collection and analysis, allowing businesses to monitor performance metrics, energy consumption, and operational efficiency remotely. This capability not only enhances responsiveness to potential issues but also aids in predictive maintenance, reducing downtime and repair costs. A study conducted by the Advanced Energy Economy Institute highlights that the adoption of remote monitoring technologies can lead to a 15%-25% reduction in energy expenses, further emphasizing the financial benefits associated with these systems.

As industries increasingly navigate the complexities of energy management, the implementation of Remote Monitoring Pumps will prove vital in driving sustainability initiatives. By leveraging advanced monitoring techniques, organizations can make informed decisions, optimizing performance while contributing to a greener future. The growing demand for energy efficiency cannot be overlooked, and incorporating these innovative tools will be pivotal in shaping a more sustainable energy landscape.

Remote monitoring pumps are a crucial component in the landscape of energy management. They enable real-time tracking and control of energy consumption, optimizing the operations of various systems like HVAC, irrigation, and industrial processes. By utilizing advanced communication technologies, these pumps transmit data regarding their performance and energy use, allowing operators to make informed decisions that can lead to substantial energy savings. According to a report by the International Energy Agency (IEA), implementing remote monitoring systems can improve energy efficiency by up to 20% in industrial applications.

One of the key advantages of remote monitoring pumps is their ability to provide instant feedback on energy consumption patterns. This data helps organizations identify inefficiencies and develop strategies to address them. For instance, a study from the U.S. Department of Energy found that facilities adopting remote monitoring solutions achieved a reduction in energy costs by as much as 15%. Furthermore, real-time alerts can prevent equipment malfunctions, which not only saves costs but also enhances operational reliability.

Tips: To maximize the benefits of remote monitoring pumps, it is essential to regularly analyze the data collected and adjust operational practices accordingly. Additionally, investing in an integrated monitoring platform can provide greater insights and automation, further optimizing energy management efforts. Always keep up-to-date with the latest trends and technologies in remote monitoring to ensure your energy management strategies remain effective.

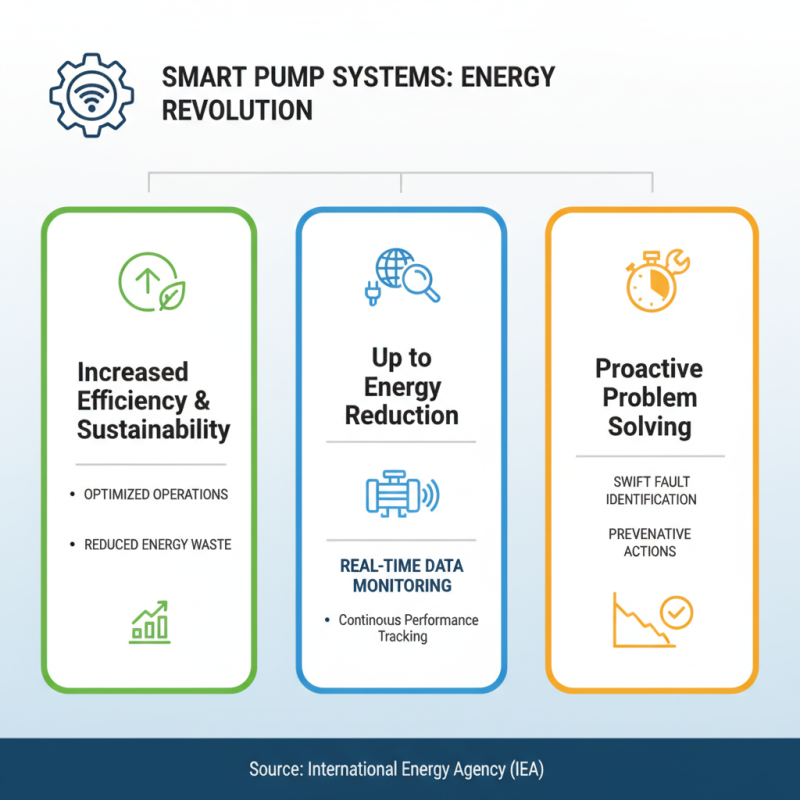

The adoption of remote monitoring pumps is revolutionizing energy management across various industries, offering significant advantages in efficiency and sustainability. According to a report by the International Energy Agency (IEA), better monitoring and control of energy systems can reduce energy consumption by up to 30%. Remote monitoring pumps facilitate this by providing real-time data, allowing organizations to optimize their operations and reduce energy waste. By continuously tracking performance metrics, companies can swiftly identify inefficiencies and take corrective actions before they escalate, leading to substantial energy savings.

Another key benefit of remote monitoring systems is their contribution to predictive maintenance. A study from the U.S. Department of Energy found that effective maintenance strategies, enabled by remote monitoring, can increase equipment lifespan by up to 50%, thereby reducing operational costs and minimizing downtime. These systems provide alerts for potential issues, enabling facilities to address problems proactively rather than reacting to failures after they occur. This predictive approach not only enhances energy efficiency but also supports overall operational reliability, ensuring that energy resources are used judiciously and effectively.

Remote monitoring pump technology is revolutionizing energy management by enhancing data accuracy and decision-making processes. With the ability to collect real-time data on pump performance, energy consumption, and system efficiency, organizations can make informed decisions that drive operational efficiency. According to a report by the International Energy Agency, improving data accuracy through remote monitoring can lead to a 10% reduction in energy consumption. This is crucial in today's climate-aware environment, where stakeholders demand greater transparency and adherence to sustainability goals.

Moreover, remote monitoring allows for predictive maintenance, reducing downtime and unnecessary costs. By analyzing data trends, operators can predict potential failures before they occur, enabling timely interventions. The U.S. Department of Energy reported that predictive maintenance can extend equipment life by up to 30%, resulting in significant savings over time. This proactive approach not only boosts efficiency but also improves overall system reliability, ensuring that energy resources are utilized to their maximum potential.

Tips for implementing remote monitoring effectively include starting with a clear data management strategy to ensure data integrity and consistency. Additionally, invest in training staff to interpret the data accurately, as informed personnel can leverage insights to enhance operational strategies. Lastly, regularly review and update monitoring parameters to adapt to changing operational needs and technologies, ensuring sustained improvements in energy management.

The implementation of remote monitoring solutions for pumps presents several challenges that need to be addressed for effective energy management. One significant obstacle is the integration of new technologies with existing systems. According to a report by the International Energy Agency, more than 70% of industrial facilities still rely on outdated monitoring methods, which can lead to compatibility issues when introducing remote technologies. This creates a barrier for organizations aiming to improve their energy efficiency and reduce operational costs.

Another challenge is the lack of skilled personnel familiar with the technologies involved in remote monitoring. As reported by the U.S. Department of Energy, there is a projected shortage of skilled workers in the energy sector, which can hinder the successful deployment of modern monitoring systems. Moreover, data security concerns remain paramount, as organizations fear potential breaches that could compromise critical operations.

Tips: To overcome these challenges, organizations should invest in training programs that familiarize staff with remote monitoring technologies. Additionally, collaborating with technology providers can streamline integration processes, ensuring that new systems work seamlessly with existing infrastructure. Regular risk assessments can also help address data security concerns and provide a proactive approach to protecting sensitive information.

| Dimension | Data Point | Description |

|---|---|---|

| Energy Savings (%) | 15-30 | Typical energy savings through remote monitoring. |

| Reduction in Downtime (%) | 40-50 | Expected reduction in equipment downtime with monitoring. |

| Cost of Implementation ($) | 5,000 - 50,000 | Initial cost range for implementing remote monitoring systems. |

| Return on Investment (ROI, years) | 1-3 | Typical ROI period for remote monitoring systems. |

| User Adoption Rate (%) | 70-85 | Percentage of users adopting the new system. |

| Common Challenges | Technical Integration, Data Security | Main challenges faced during implementation. |

The rapid evolution of remote monitoring technology is reshaping energy management strategies across numerous industries. According to a report by MarketsandMarkets, the global remote monitoring market is projected to grow from $26.09 billion in 2020 to $75.57 billion by 2025, indicating a significant shift towards more efficient energy management systems. This trend highlights the increasing reliance on innovative technologies to optimize energy consumption and reduce operational costs.

In the realm of energy management, the integration of IoT devices and advanced analytics has become essential. The International Energy Agency (IEA) reported that the adoption of smart grid technologies could lead to a reduction in energy losses of up to 30%. Remote monitoring systems facilitate real-time data analysis, enabling organizations to swiftly identify inefficiencies and implement corrective measures. Furthermore, predictive maintenance, powered by machine learning algorithms, allows for proactive interventions, reducing downtime and extending the lifespan of critical components.

As the demand for sustainable practices grows, the future of remote monitoring technology in energy management looks promising. Emerging trends such as enhanced data collection capabilities and the integration of artificial intelligence will empower organizations to make informed decisions about energy usage. The emphasis on data-driven approaches not only aids in regulatory compliance but also fosters a culture of sustainability, supporting long-term strategic goals. As industries increasingly adopt these technological advancements, the potential for significant energy savings and environmental stewardship becomes more attainable.