In today’s world, noise reduction is crucial in various applications. A Low Noise Pump serves this need effectively. These pumps minimize sound, enhancing comfort in residential, commercial, and industrial settings. Noise pollution can disrupt peace, making quiet performance a priority.

Selecting the right Low Noise Pump often requires careful thought. It’s not just about sound levels; efficiency is also key. Some models may excel in quietness but lack durability or energy efficiency. This trade-off can lead to frustration. Users must reflect on their specific needs and make educated choices.

Aside from noise control, a Low Noise Pump can improve overall productivity. In hospitals or libraries, silent operation is vital. The right pump minimizes distractions, allowing for a more focused environment. Yet, the challenge remains. How can we find the best options? Exploring various products can seem overwhelming, but it is essential for a successful outcome.

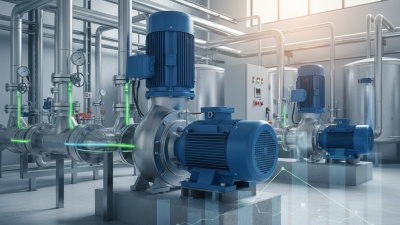

Choosing the right pump is crucial for maintaining a quiet environment. Many industries require low noise pumps to ensure a peaceful atmosphere. These pumps excel in performance while minimizing sound output. In applications ranging from aquariums to HVAC systems, silent operation is essential.

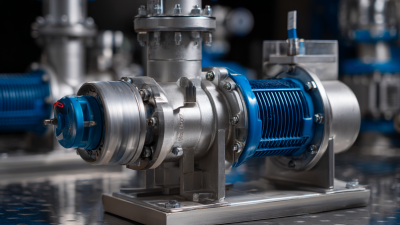

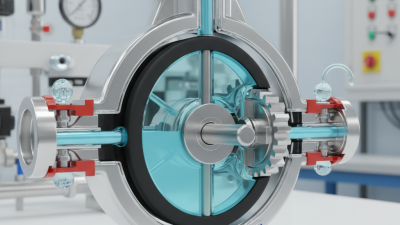

When assessing quiet performance, consider the pump's design and materials. Some designs feature noise-dampening technology. Others rely on specific materials to absorb sound waves. Look for details such as motor type and operational speed. It’s important to recognize that even low noise pumps can create vibrations. These vibrations may lead to unwanted noise if not properly managed.

Installation plays a significant role in overall performance. Proper mounting can reduce noise significantly. If a pump rattles or vibrates, it can be frustrating. Often, users overlook routine maintenance. Neglecting this can lead to increased noise and decreased efficiency. Pay attention to these aspects to ensure a quieter operation.

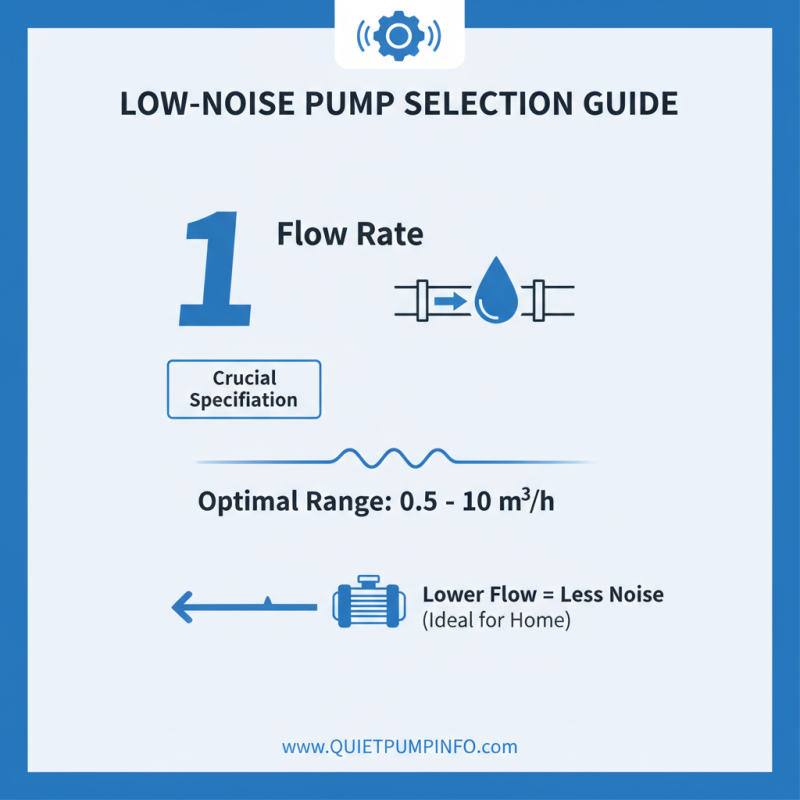

When selecting low noise pumps, certain specifications stand out. Flow rate is crucial. It measures how much fluid a pump can move over time. Reports indicate optimal flow rates often range from 0.5 to 10 cubic meters per hour for quiet applications. Lower flow rates usually produce less noise, making them ideal for residential use.

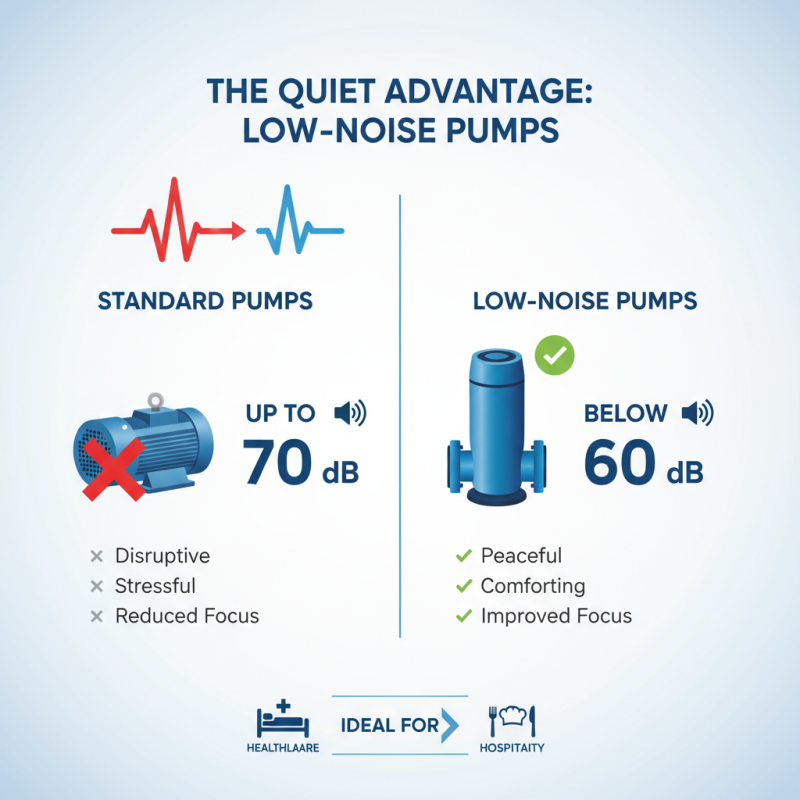

Another important factor is the noise level itself. Typically, low noise pumps operate at sound levels below 60 dB. This is essential for environments needing minimal disruption. In healthcare settings, for instance, maintaining a serene atmosphere is vital. A pump emitting 40 dB is hardly noticeable. However, choosing a pump with higher dB ratings might lead to distractions.

Lastly, energy efficiency cannot be overlooked. Reports show that efficient pumps can reduce operational costs by up to 30%. This is significant in continuous operation scenarios. Consider how body vibrations affect overall performance. Installing pumps on vibration dampening bases can further decrease noise. Despite the advancements in pump design, users should remember that perfect silence is challenging to achieve. Always assess specific needs and conditions before making a choice.

Noise reduction technologies play a crucial role in enhancing pump performance. These innovations focus on minimizing sound levels while maintaining efficiency. Various methods are employed, including sound insulation and vibration dampening. These techniques can greatly decrease the noise produced during operation.

Implementing advanced designs can also aid in noise reduction. For example, optimizing impeller shapes can minimize turbulence, which directly impacts sound levels. However, not all methods may achieve the desired balance between noise reduction and efficiency. Some solutions might add complexity, potentially leading to higher maintenance needs.

Ultimately, understanding the impact of noise reduction technologies is vital. While quieter pumps create a more comfortable environment, their long-term efficiency must be carefully considered. As manufacturers continue to explore new technologies, it’s essential to address any compromises that may arise during the design and installation stages. Each step requires careful evaluation to ensure optimal performance without sacrificing reliability.

Low noise pumps are essential in both residential and industrial settings. In homes, these pumps contribute to a peaceful environment. Many homeowners face noise disturbances from HVAC systems, swimming pools, and water features. Research indicates that noise levels above 50 dB can disrupt daily activities. Low noise pumps operate below this threshold, often ranging between 30 to 40 dB, ensuring quiet performance.

In industrial applications, the importance of noise reduction is equally critical. Factories and production facilities often deal with considerable machinery noise. The Occupational Safety and Health Administration (OSHA) states that prolonged exposure to noise levels above 85 dB can cause hearing loss. Implementing low noise pumps can significantly reduce overall noise levels. This not only enhances worker comfort but may also boost productivity.

Challenges remain in balancing efficiency and noise levels. Some low noise pumps may not offer the same flow rates as their louder counterparts. Industry professionals constantly seek improvements. Ensuring that pumps meet noise regulations while maintaining performance is vital. Failure to find this balance can lead to increased operating costs and reduced system efficacy.

| Pump Model | Noise Level (dB) | Flow Rate (GPM) | Power Consumption (W) | Application Type |

|---|---|---|---|---|

| Model A | 45 | 10 | 100 | Residential |

| Model B | 50 | 15 | 120 | Industrial |

| Model C | 42 | 12 | 90 | Residential |

| Model D | 48 | 20 | 150 | Industrial |

| Model E | 46 | 9 | 80 | Residential |

| Model F | 49 | 18 | 140 | Industrial |

| Model G | 44 | 11 | 95 | Residential |

| Model H | 47 | 14 | 110 | Industrial |

| Model I | 43 | 10 | 85 | Residential |

| Model J | 51 | 16 | 130 | Industrial |

In various applications, low noise pumps are essential for ensuring quiet operations. According to recent studies, a significant reduction in noise can improve work environments, especially in sectors like healthcare and hospitality. The average noise level of standard pumps can reach up to 70 dB, while low noise models often operate below 60 dB. This difference can be crucial in sensitive environments.

When comparing industry-leading models, factors such as sound dampening technology and pump design play a pivotal role. For instance, some pumps utilize advanced materials that absorb sound. These designs can cut noise levels significantly. On a performance scale, models rated above 4.5 stars tend to offer both efficiency and quieter operation. However, some users have reported issues with reliability in low noise systems, indicating the need for consistent quality testing.

Decibel levels are not the only measurement. Vibration levels must also be monitored. High vibration can lead to increased wear and tear, ultimately affecting performance. Monitoring these parameters can aid in selecting the right model. Careful consideration is needed when matching a pump to its intended application. Some options may excel in quiet operation, but may lack in durability or efficiency. Balancing these aspects is key.