In the realm of construction and industrial applications, the importance of effectively managing excess water cannot be overstated. Dewatering pumps play a crucial role in this process, ensuring that sites remain safe and operational despite adverse weather conditions or groundwater issues. According to John Smith, a renowned expert in hydraulic engineering, "A reliable dewatering pump is an essential tool for maintaining efficiency and safety in water-logged environments." His insights underline the necessity for high-performance equipment in projects ranging from small-scale landscaping to large infrastructure developments.

When tackling water removal challenges, selecting the right dewatering pump becomes paramount. The market offers a variety of options, each designed to cater to specific needs and conditions. As construction projects become increasingly complex, understanding the capabilities and limitations of these pumps is vital for contractors and site managers alike. In this article, we delve into the top 10 dewatering pumps available today, highlighting their features, efficiency, and suitability for diverse applications. Whether for emergency use or regular site management, having the right dewatering pump can significantly enhance productivity and safety.

Dewatering pumps play a critical role in various industries by efficiently removing excess water from construction sites, mining operations, and agricultural fields. Their importance stems from the need to maintain a dry working environment, which not only prevents equipment damage but also enhances worker safety. Excess water accumulation can lead to structural hazards and hinder operations, making dewatering pumps essential tools for site management and project success.

The various types of dewatering pumps, including submersible, centrifugal, and diaphragm pumps, cater to different water removal needs and site conditions. Each type offers unique advantages, such as portability or the ability to handle solid-laden water. Selecting the right dewatering pump is crucial for ensuring quick and effective water removal, enabling projects to stay on track and avoid costly delays. With their capacity to handle large volumes of water, these pumps are invaluable in preventing flooding and ensuring optimal working conditions across diverse applications.

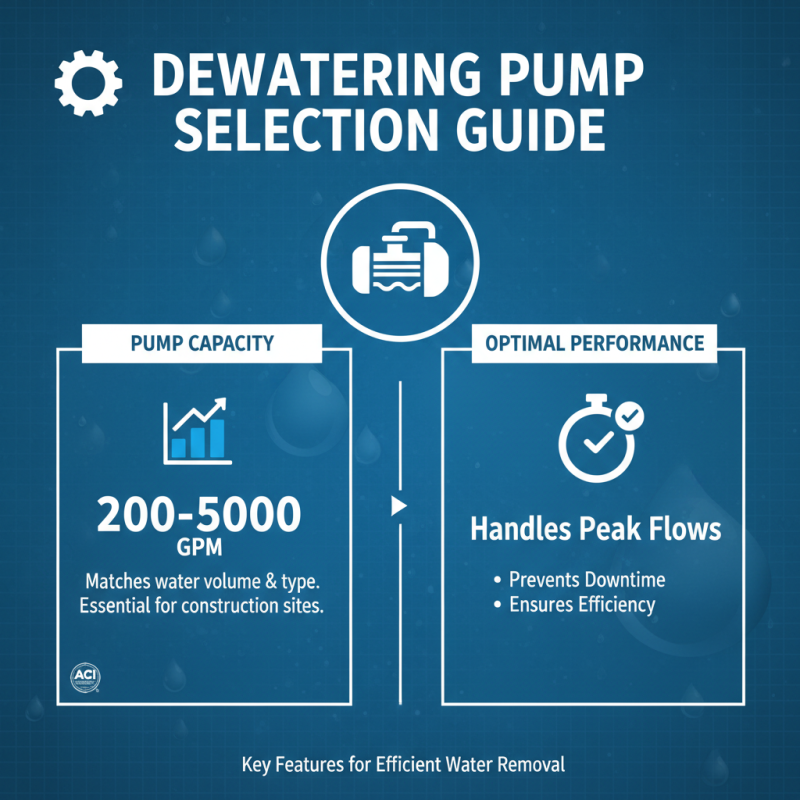

When selecting a dewatering pump, several key features should be at the forefront of your decision-making process to ensure optimal performance for efficient water removal. First and foremost, pump capacity is critical. According to the American Concrete Institute, the right pump should match the volume and type of water needing removal. For construction sites, where large quantities of water can accumulate, pumps with a capacity ranging from 200 to 5,000 gallons per minute (GPM) are often recommended. Selecting a pump that can handle peak flows while maintaining efficiency is essential to prevent downtime and operational delays.

Another significant consideration is the type of pump. Options typically include submersible and centrifugal pumps, each with its distinct advantages. A report from the Water Environment Federation indicates that submersible pumps are generally more efficient in deeper applications, as they can operate entirely underwater, reducing the need for additional piping. Additionally, factors such as power source, portability, and the pump’s ability to handle solids should also be evaluated. Pumps equipped with durable materials and features like adjustable float switches can improve longevity and adaptability in diverse environments, making them well-suited for a variety of dewatering tasks. Investing in a pump with the right specifications can save both time and resources, enhancing overall project efficiency.

When selecting a dewatering pump for various applications, it’s important to consider the specific needs of your project, such as the volume of water to be removed, the type of debris that may be present, and the environment in which the pump will operate. Dewatering pumps are versatile and can be used in construction sites, basements, and even for agricultural drainage. Choosing the right pump can significantly enhance efficiency and save time and resources.

Tips for selecting the right dewatering pump include assessing the maximum flow rate required for your project and ensuring that the pump can handle solids if necessary. Additionally, consider the power source; some pumps operate on electricity while others may require fuel. It’s also worthwhile to evaluate the weight and portability of the pump if it needs to be moved frequently.

Another important aspect to think about is the pump's durability and maintenance needs. Pumps made from high-quality materials can withstand harsh conditions and require less frequent repairs. Always read reviews and compare specifications to ensure that the pump will meet your demands effectively. Remember, investing in a high-performing dewatering pump can greatly contribute to the success of your project, keeping water levels manageable and operations running smoothly.

When evaluating the performance metrics of leading dewatering pumps, several key factors come into play that determine their efficiency and suitability for various applications. Flow rate, head capacity, and power consumption are critical metrics to consider. The flow rate indicates the volume of water that can be removed over a specific time, while the head capacity signifies the maximum height at which the pump can effectively lift water. An efficient dewatering pump should strike a balance between these metrics, ensuring swift water removal without excessive energy use.

In addition to flow and head, the durability and maintenance requirements of the pump also impact its overall performance. A pump constructed from high-quality materials can withstand harsh environments and extended usage without significant wear. The ease of maintenance is another important factor; pumps that are designed for quick disassembly and cleaning will reduce downtime and operational costs. By focusing on these performance metrics—flow rate, head capacity, durability, and maintenance—users can make informed decisions that optimize their dewatering processes while ensuring reliability and efficiency.

Maintaining dewatering pumps in optimal condition is crucial for ensuring their efficient performance and longevity. Regular maintenance practices include checking the pump for any signs of wear and tear, especially on the impeller and casing. It is essential to clean the intake strainer to prevent debris accumulation, which can hinder operation and reduce water flow efficiency. Additionally, monitoring the oil levels in the motor and gearbox and changing them as necessary will help avoid mechanical failures.

Another important aspect of maintenance is to inspect the electrical connections and wiring. Loose or corroded connections can lead to power interruptions and decreased operational effectiveness. Furthermore, operators should conduct routine testing of the pump's operational parameters, such as flow rate and pressure, to ensure they are within optimal ranges. Proper storage is also vital; if the pump is not in use for an extended period, it should be drained, cleaned, and stored in a dry location to prevent deterioration from rust or other environmental factors. With consistent attention to these maintenance tips, dewatering pumps can operate effectively and reliably, minimizing the chances of unexpected breakdowns.

This chart compares the flow rates of the top 10 dewatering pumps measured in gallons per minute (GPM). Efficient water removal is crucial for various applications, and understanding the performance of each pump helps in making an informed choice.