Excavation Water Pumps are critical tools in construction and mining sectors. According to a 2022 report by the Global Construction Industry, the market for water pumps is projected to grow by 8% annually. This growth highlights the importance of efficient water management solutions.

Choosing the right Excavation Water Pump can significantly affect project timelines. For example, inadequate pumping capacity can stall operations, leading to increased costs. Many contractors overlook the specific needs of their projects, resulting in improper equipment. It's essential to understand that not all pumps are created equal.

The efficiency of an Excavation Water Pump often determines how quickly a site can be prepared. High-quality pumps reduce downtime and enhance safety. However, the wrong choice can lead to frustrations. Contractors must reflect on their unique requirements before purchasing. Balancing costs with efficacy is crucial in today's competitive landscape.

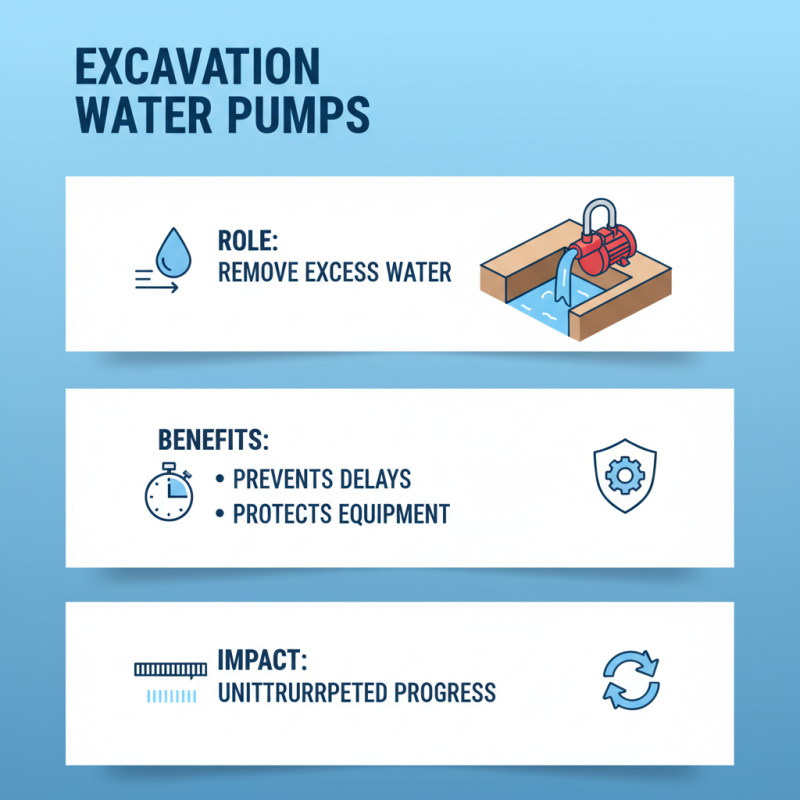

Excavation water pumps play a crucial role in construction and landscaping projects. These pumps help remove excess water from job sites, preventing delays. Standing water can hinder progress and damage equipment. A reliable water pump ensures that excavation can continue without interruption.

When selecting a water pump, consider the pump's capacity and efficiency. Not all pumps are suited for every job. Some might struggle with high volumes, while others may be too powerful for smaller sites. Assessing the specific needs of each project is vital. A mismatch can lead to unnecessary complications.

In many cases, users overlook maintenance. Regular checks can extend a pump's lifespan significantly. Neglecting simple upkeep can lead to breakdowns at critical moments. It’s essential to invest time in understanding how a pump operates. This knowledge equips operators to handle unexpected issues effectively. Mistakes can be costly, both in time and resources.

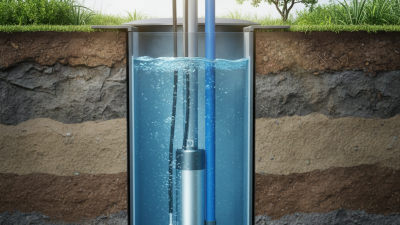

When selecting an excavation water pump, it's crucial to understand the types available for different applications. Submersible pumps are ideal for deep pits. They operate underwater and can handle large volumes efficiently. These pumps can be a bit tricky to maintain due to the exposure to debris and sediments.

Another option is the centrifugal pump. These are great for transferring water from one location to another. They are versatile and can work in various environments. However, they might struggle with thick sludge. This limitation could affect pump longevity.

Tips: Regularly check for clogs in your pumps. This can help in avoiding unexpected breakdowns. Also, consider the pump’s power requirements before purchase to ensure adequate performance.

If you need something for smaller or temporary projects, diaphragm pumps may be your friend. They handle viscous fluids well but often require frequent maintenance. Remember, the right pump choice can save you time and money in the long run.

When selecting a water pump for excavation, key features matter. Start with the pump's power source. Electric pumps offer convenience but face limitations in remote areas. Gas-powered pumps provide mobility but require fuel storage. Understand your site conditions before making a choice.

Next, consider the pump's capacity. Look for pumps that can handle the volume of water you expect. A smaller pump may struggle in heavy rain, while an oversized pump can be inefficient. Tarps and drainage systems might help, but they aren't always reliable.

Portability is another important consideration. Some projects require moving the pump frequently. Lighter models make it easier, but they may compromise on power. Reflect on your past experiences. Sometimes, the perfect balance is hard to find. Identifying the right fit for your needs can be a challenge.

| Pump Model | Flow Rate (GPM) | Max Head (ft) | Power Source | Weight (lbs) |

|---|---|---|---|---|

| Model A | 100 | 25 | Electric | 30 |

| Model B | 150 | 30 | Gas | 50 |

| Model C | 200 | 40 | Diesel | 65 |

| Model D | 120 | 26 | Electric | 28 |

| Model E | 180 | 35 | Gas | 55 |

| Model F | 160 | 32 | Electric | 40 |

| Model G | 140 | 28 | Diesel | 70 |

| Model H | 110 | 24 | Gas | 37 |

| Model I | 130 | 29 | Electric | 35 |

| Model J | 170 | 42 | Diesel | 85 |

When selecting an excavation water pump, consider various brands and models available. The market offers numerous solutions tailored to different project needs. The right pump can save time and reduce operational costs. Each model boasts distinct features, such as variable speed settings or automatic shut-off systems. Think about how these features apply to your specific excavation tasks.

Some pumps are lightweight and portable. They may suit smaller job sites, making movement easy. Others provide more power and capacity, ideal for larger operations. It’s crucial to match the pump to the workload. Some models may struggle on heavy-duty sites, showing limitations that can impact work efficiency. Choosing the wrong size can result in frequent breakdowns, leading to delays.

Investing time in research is essential. User reviews can offer insights into reliability and performance. Users often highlight durability as a crucial factor. However, some may overlook maintenance requirements. Regular upkeep is vital for optimal pump performance. Ignoring this can lead to poor results, diminishing the pump's lifespan. Make sure to evaluate your options carefully before making a decision.

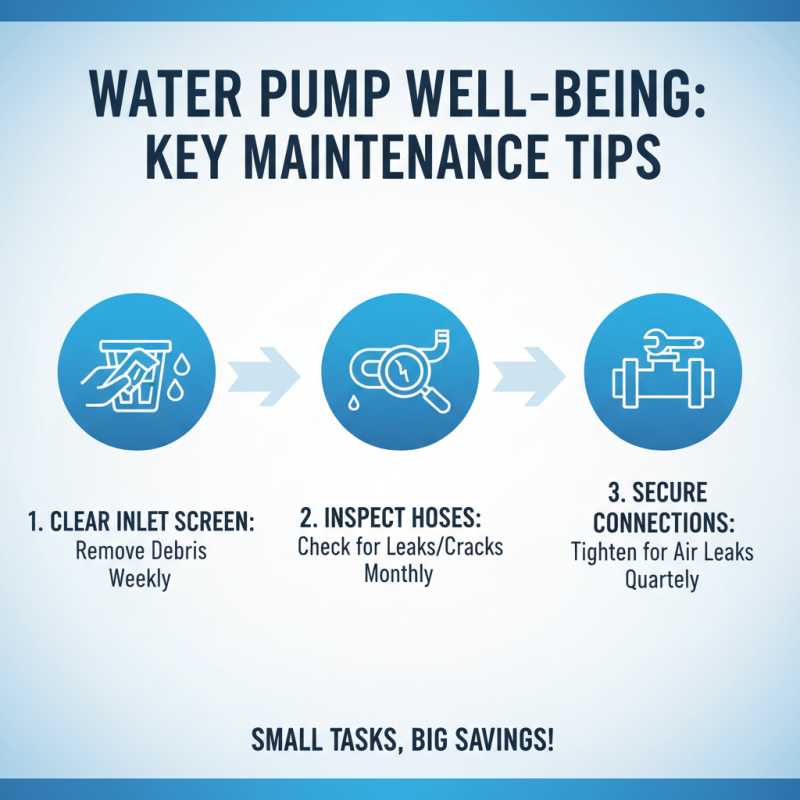

Proper maintenance is crucial for effective water pump performance. Regularly check the pump’s inlet screen for debris. Clean it to prevent clogs. Inspect hoses for leaks or cracks, which can lead to inefficiencies. Additionally, ensure that connections are tight to minimize air leaks. These small tasks can save you from larger issues down the road.

Consider the pump’s environment. Excessive dirt or sand can hinder operation. Make efforts to keep the area around the pump clean. Also, check the oil level frequently and replace it as needed. Pay attention to any unusual sounds or vibrations during operation. Such signs may indicate a need for deeper examination.

Maintenance can often feel tedious. Yet, ignoring these tasks invites bigger problems. Create a simple schedule for maintenance checks. This can help eliminate procrastination and ensure optimal pump performance. A little attention now can prevent extensive downtime later.