In the dynamic landscape of fluid management, the significance of choosing the right pumping technology cannot be overstated. Vortex pumps have emerged as a crucial component for industries looking to optimize efficiency and reduce downtime in fluid handling operations. According to a recent industry report by the Global Fluid Control Association, the demand for vortex pumps is projected to grow by 15% annually as businesses increasingly recognize their ability to handle solids-laden fluids effectively.

Experts in the field, such as Dr. Emily Turner, a renowned mechanical engineer at the Fluid Dynamics Research Institute, underscore the importance of vortex pump technology. She stated, "The unique design of vortex pumps enables them to maintain high efficiency while minimizing wear and tear, which is essential for long-term operational success." This assertion is further supported by findings that suggest vortex pumps not only provide superior performance in various applications but also contribute to significant cost savings by reducing maintenance frequency and energy consumption.

As we explore the top 10 vortex pumps of 2023, it is vital to consider their performance metrics, application versatility, and technological innovations that set them apart in the realm of efficient fluid management.

When selecting vortex pumps for fluid management, several key considerations should be prioritized to ensure optimal performance and efficiency. Firstly, understanding the specific application and fluid characteristics is crucial. According to a recent industry report by Grand View Research, the global vortex pump market is expected to reach USD 1.73 billion by 2025, driven largely by the demand for effective fluid handling in various sectors, including wastewater treatment and industrial processing. Therefore, knowing the viscosity, temperature, and chemical compatibility of the fluids involved will help in choosing a pump designed to handle such specific challenges.

Another important factor is the pump's operational efficiency. A study conducted by the Hydraulic Institute indicated that vortex pumps can achieve efficiencies exceeding 75% under optimal conditions. However, this depends heavily on factors such as impeller design and system configuration. Additionally, maintenance requirements and the total cost of ownership should not be overlooked. The right pump can minimize downtime and maintenance costs, which can collectively impact operational budgets significantly. By focusing on these considerations, industries can effectively enhance their fluid management systems, ensuring reliability and long-term performance.

| Model | Flow Rate (GPM) | Max Head (ft) | Power (HP) | Material | Weight (lbs) |

|---|---|---|---|---|---|

| Vortex Pump A | 150 | 40 | 5 | Stainless Steel | 80 |

| Vortex Pump B | 200 | 35 | 7.5 | Cast Iron | 100 |

| Vortex Pump C | 180 | 50 | 5.5 | Aluminum | 90 |

| Vortex Pump D | 170 | 45 | 6 | Polypropylene | 85 |

| Vortex Pump E | 160 | 30 | 4 | PVC | 75 |

| Vortex Pump F | 220 | 55 | 8 | Fiberglass | 110 |

| Vortex Pump G | 190 | 38 | 6.5 | Stainless Steel | 95 |

| Vortex Pump H | 210 | 42 | 7 | Cast Iron | 100 |

| Vortex Pump I | 175 | 33 | 5 | Aluminum | 88 |

| Vortex Pump J | 195 | 48 | 6.2 | Polypropylene | 92 |

In 2023, the demand for efficient vortex pumps in fluid management has significantly risen, driven by their versatility and reliability in handling various liquids, including slurries and viscous fluids. Research from the Fluid Handling Industry Association indicates that vortex pumps can achieve flow rates of up to 6000 gallons per minute, making them suitable for applications in wastewater treatment, mining, and industrial processes. The unique design of vortex pumps minimizes clogging risks, a crucial feature that enhances operational efficiency, particularly in environments where solid particles may be present.

Key features of the most efficient vortex pumps emerging this year include energy efficiency and advanced materials. Many top models now incorporate energy-saving technologies that can reduce operational costs by up to 30% compared to conventional pump systems. Furthermore, the use of corrosion-resistant materials and innovative sealing solutions allows vortex pumps to operate in harsh conditions, extending their service life and reducing maintenance costs. A recent report from the International Water Association highlights that the integration of smart controls in newer pump designs further optimizes performance, providing real-time monitoring and adjustments to ensure peak efficiency in various fluid management scenarios.

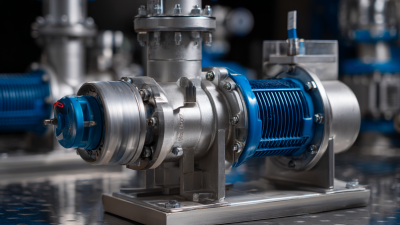

In the realm of fluid management, selecting the right vortex pump is crucial for optimal performance and efficiency. A comparative analysis of leading vortex pump brands can provide insights into their operational capabilities and suitability for various applications. Recent studies focusing on the hydrodynamic characteristics of different pumping mechanisms reveal significant differences in performance between vane-type pumps and self-priming pumps under conditions of cavitation. Understanding these differences can guide users in selecting a pump that aligns with their specific fluid management needs.

Moreover, recent evaluations of transient predictions for pump-jets have highlighted the impact of design elements like camber and attack angles on flow dynamics. Such analyses reveal how the configuration of ducts can affect pump efficiency and fluid displacement. This comparative perspective of different pump types and their configurations not only aids in identifying the most effective vortex pumps available in 2023 but also emphasizes the importance of considering hydrodynamic behavior and internal flow mechanisms in the selection process.

When it comes to selecting the best vortex pumps for efficient fluid management in 2023, user reviews play a crucial role in guiding potential buyers towards the most reliable options. Customers often highlight features such as energy efficiency, reliability, and the ability to handle solids or abrasive materials without clogging. For instance, many users praise the XYVortex 2000 model for its robust performance in challenging environments, ensuring smooth operation and minimal maintenance needs. Reviews emphasize the pump's durable construction, making it an ideal choice for both residential and industrial applications.

Additionally, user feedback on design and usability significantly influences purchasing decisions. The Apex Vortex CPX series is frequently mentioned for its intuitive control system and user-friendly installation process, making it accessible even for those new to vortex pump technology. Customers appreciate detailed manuals and responsive customer support, which enhance their overall experience. As buyers delve into these reviews, they find valuable insights that not only help in selecting the right vortex pump but also in optimizing their fluid management processes for maximum efficiency.

In 2023, the advancement of vortex pump technologies has significantly enhanced their performance for efficient fluid management across various industries. Recent reports indicate that integrating smart sensors and IoT capabilities has allowed vortex pumps to monitor real-time performance, optimize energy consumption, and reduce operational costs by up to 25%. These innovations not only improve efficiency but also minimize downtime, offering businesses a competitive edge in resource management.

Moreover, manufacturers are increasingly utilizing advanced materials that resist corrosion and wear, thereby prolonging the lifespan of vortex pumps. A study by the Fluid Handling Institute noted that pumps with enhanced chemical resistance have seen a 30% increase in durability, making them a superior choice for harsh operating environments. These developments ensure that vortex pumps remain reliable in diverse applications, from agricultural to wastewater management.

**Tips:** When selecting a vortex pump, consider models equipped with built-in monitoring systems to track performance and detect potential issues early. Additionally, opting for pumps made with high-durability materials can save costs on replacements and maintenance in the long run. Remember, compatibility with existing systems is crucial—always review specifications before making a decision.