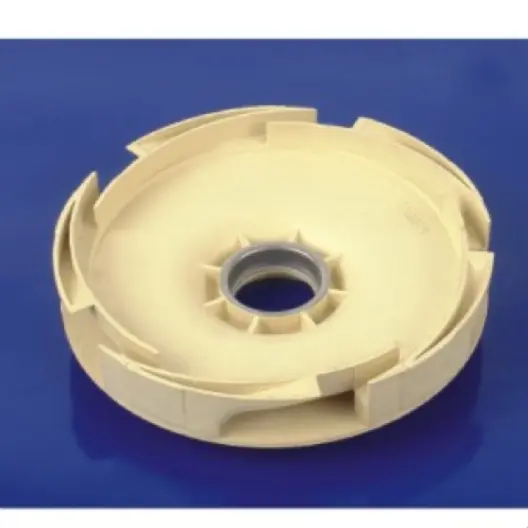

Plastic Guide Vane For The Water Pumps

Product description

Guide vane is mainly applied in self-filling injection pumps or other pump types, able to replace volute, with higher precision and equivalent efficiency to that of volute. Its rational design and exquisite process can effectively ensure the performance of water pumps. The water inlet is embedded with stainless steel bush fitting, able to effectively resist destruction arising from cavitation of water pumps.

Plastic guide vanes also are engineered components used to direct or regulate fluid flow (e.g., air, water, or gases) in various mechanical systems. Made from high-performance polymers, they offer advantages such as lightweight construction, corrosion resistance, and design flexibility compared to traditional metal vanes. The guide vane is mainly used for jet pumps or other pumps, which can replace the stainless steel volute, with higher precision, and its quantitative and exquisite process effectively package the performance of the water pump.

We are in pursuit of effective process control methods, to lower the defective rate of products, to enhance the degree of customer satisfaction based on a self-contained quality management system, and to allow the conception of “the following working procedure is the user of the previous working procedure” to be profoundly implanted into the mind of our each staff member.

We uphold the conception of quality” these is no best, but better only” and regards customer demands ad our first target, we shall establish more self-contained quality assurance system, place stress on implementation of quality responsibility system for responsible people to be specified for the entire process from product design and development to after service, and sieve “PDCA” cycle as the radical impetus on sustainable improvement of enterprice.

Plastic guide vanes play a pivotal role in optimizing fluid dynamics across industries, balancing cost, durability, and performance. Their design and material selection must align with operational demands (e.g., temperature, pressure, fluid type). As material science advances, plastic guide vanes are poised to replace traditional metal variants in lightweight, high-efficiency systems.